This week we welcome Justine and Robinson of Sailorama to the blog! Their latest sailboat project is a 40 foot Vennekens Koral Pilothouse Sloop named Inesperada, or Ines for short.

'She came to us for free, in very rough condition. We have ripped out much of the old cabinetry, headliner, electrical systems, and plumbing. We have installed new running and standing rigging, a new water tank, galley - and the work continues.'

In the latest episode from Sailorama, Justine Yearwood takes us along their time in Guatamala, where their boat undergoes some much-needed repairs. Armed with a crucial cargo of TotalBoat epoxy and fairing compound, Justine and Robinson dive into a range of projects to tackle boat maintenance, all while contending with the region's unpredictable weather. The video provides great insights into how TotalBoat’s High Performance Epoxy Resin and TotalFair Epoxy Fairing Compound can be used in various applications, making it a valuable watch for any DIY boat owner or maker.

Their first project involved addressing the various shallow gouges created while sanding. The TotalFair Epoxy Fairing Compound quickly became a favorite for smoothing out these areas. Instead of having to mix multiple components as would traditionally be required, Justine praised the ease of the fairing compound. The simplicity of a one-to-one mix and the smooth application made quick work of filling imperfections. With the extreme heat of Guatemala, Justine noted that the compound set in about 10 to 15 minutes.

The next day, the team returned to find the TotalFair compound had set perfectly and was ready for sanding. It proved easy to work with, sanding down smoothly with an 80-grit random orbit sander. This step was crucial in preparing the keel for additional epoxy work. With rust threatening to compromise the structure, they applied a rust converter, followed by another round of epoxy to seal everything in place. The fairing compound’s compatibility with metal surfaces proved especially useful in ensuring the keel was ready for the next steps.

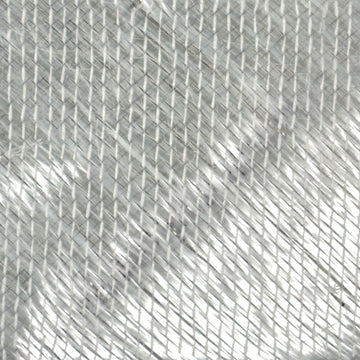

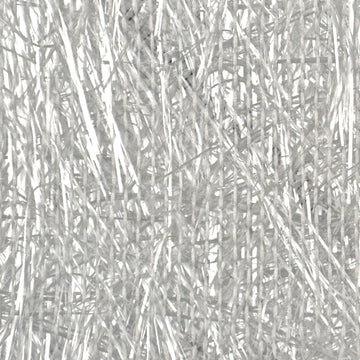

Once the keel was treated, it was time to tackle a larger structural issue: the delamination caused by rust. Here, they turned to TotalBoat’s High Performance Epoxy Resin with Slow Hardener to apply biaxial fiberglass cloth for reinforcement. Justine highlighted how this non-blushing epoxy simplifies the process, as there’s no need to remove the amine blush before applying subsequent layers. This ease of use was essential when layering multiple sheets of fiberglass cloth to encapsulate and protect the keel.

As the team progressed, they used the fairing compound once again to smooth out the keel, ensuring a flawless surface for painting. The compound’s versatility was evident, as it not only worked on small imperfections but also played a key role in preparing larger areas for finishing. This was especially helpful when preparing the deck, where anti-skid surfaces had been removed and needed to be leveled before applying new materials.

In addition to tackling repairs on the keel and deck, Justine also demonstrated her resourcefulness by crafting new hatches using scrap wood, epoxy, and TotalFair. After removing the boat's old, leaky hatches, she decided to build new ones from scratch, starting with the basic wooden frames. To ensure the new hatches were durable and watertight, Justine used High Performance Epoxy to bond the wood and fiberglass together. She then applied the TotalFair compound to shape and smooth the surfaces, creating a seamless finish. The combination of these materials provided the strength and waterproofing necessary to keep rainwater out and protect the interior of the boat. Despite the challenges of working in the humid, rainy conditions of Guatemala, Justine’s careful application of the epoxy and fairing compound resulted in custom hatches that were both functional and well-crafted.

The video concludes with an ambitious window repair project. Using leftover plywood and fiberglass, the team crafted new hatches and port lights for the boat. Once again, TotalBoat’s epoxy played a pivotal role in ensuring the wood and fiberglass would hold up against the elements. By the end of the video, the team had made significant progress on their boat, all while showing just how versatile and effective TotalBoat products are for both major repairs and finer finishing touches. Be sure to checkout Sailorama on YouTube to continue following along with their journey!