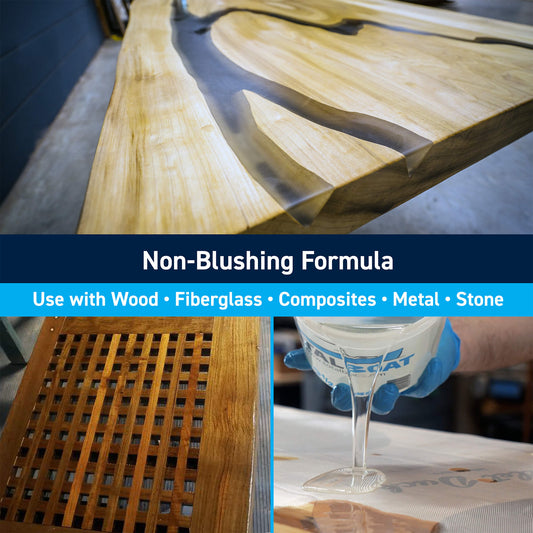

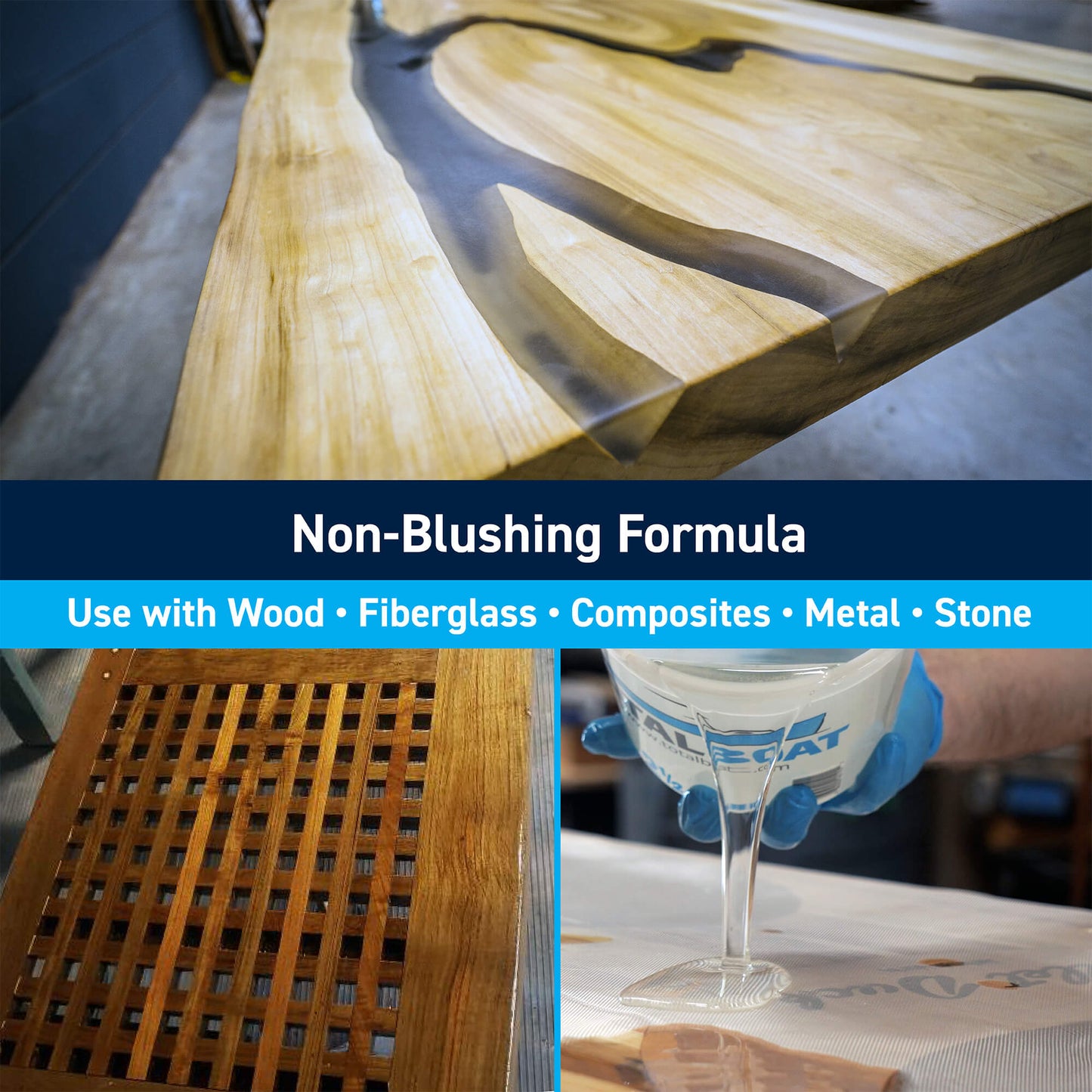

ULTRA CLEAR, NON-BLUSHING

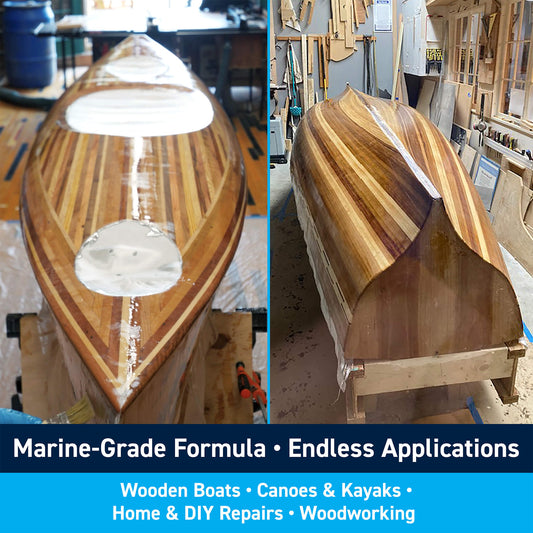

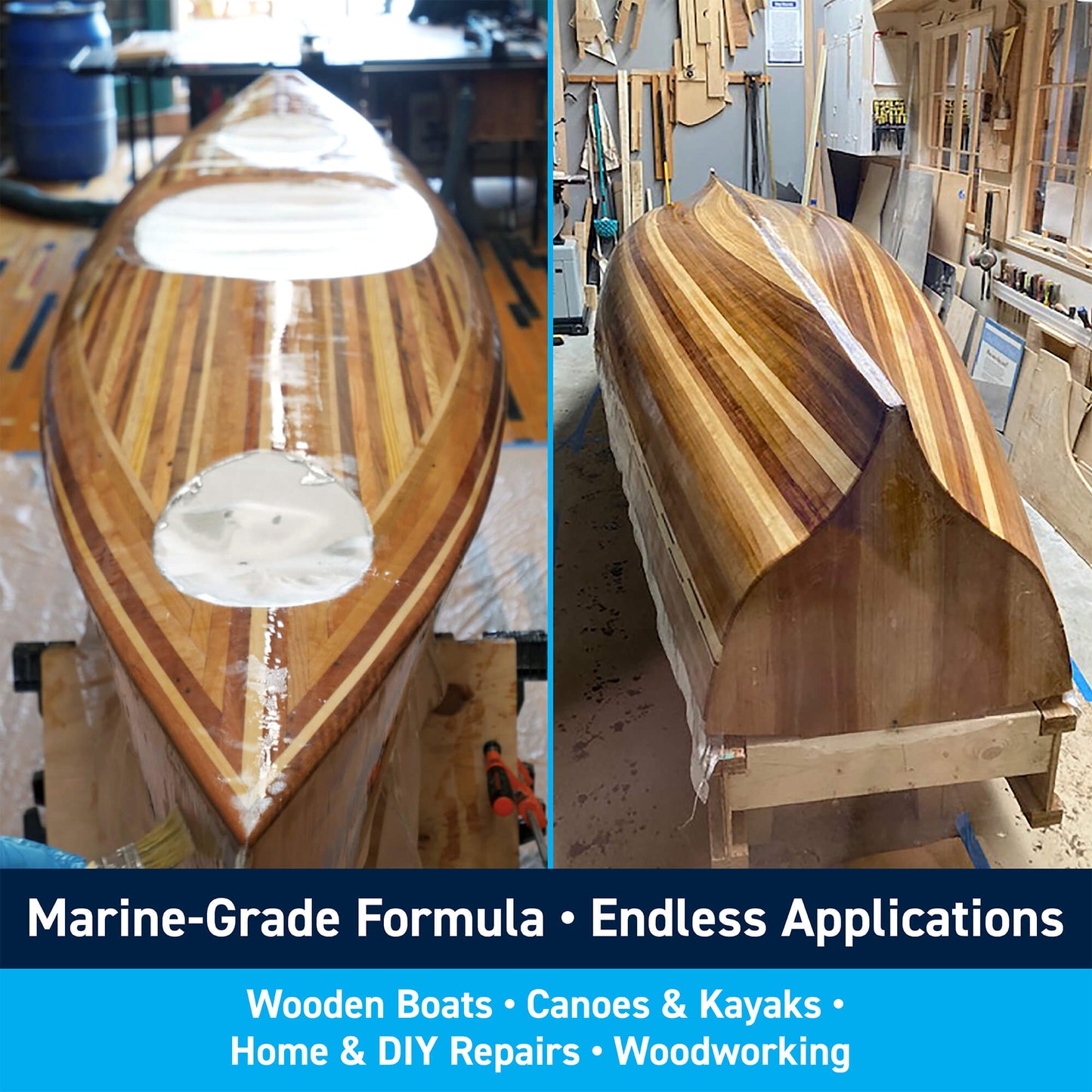

Great for wooden boat building, clear coating and woodworking.GREATER FLEXIBILITY

Handles stresses and loads better than traditional epoxies.LOW VISCOSITY

Ideal for laminating, coating and wetting out fiberglass cloth.EPOXY SELECTION GUIDE

This chart will help you choose the right epoxy systemClear High Performance Epoxy Kits

Clear High Performance Epoxy Kits

ULTRA CLEAR, NON-BLUSHING

Great for wooden boat building, clear coating and woodworking.GREATER FLEXIBILITY

Handles stresses and loads better than traditional epoxies.LOW VISCOSITY

Ideal for laminating, coating and wetting out fiberglass cloth.EPOXY SELECTION GUIDE

This chart will help you choose the right epoxy systemCouldn't load pickup availability

Premium, easy-to-use, low-viscosity, clear epoxy resin system in a convenient kit

Use TotalBoat High Performance Epoxy Resin for a moisture-resistant cure that's more clear and slightly more flexible than traditional 5:1 epoxy resin systems. Its greater elasticity is especially ideal for building and repairing wooden boats prone to flexing during use or with fluctuations in temperature and humidity.

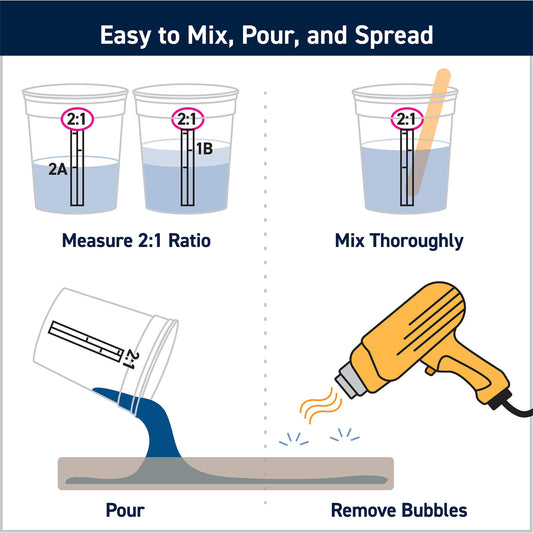

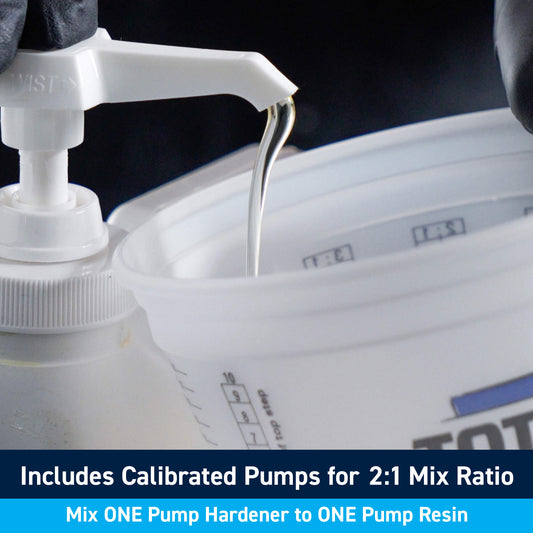

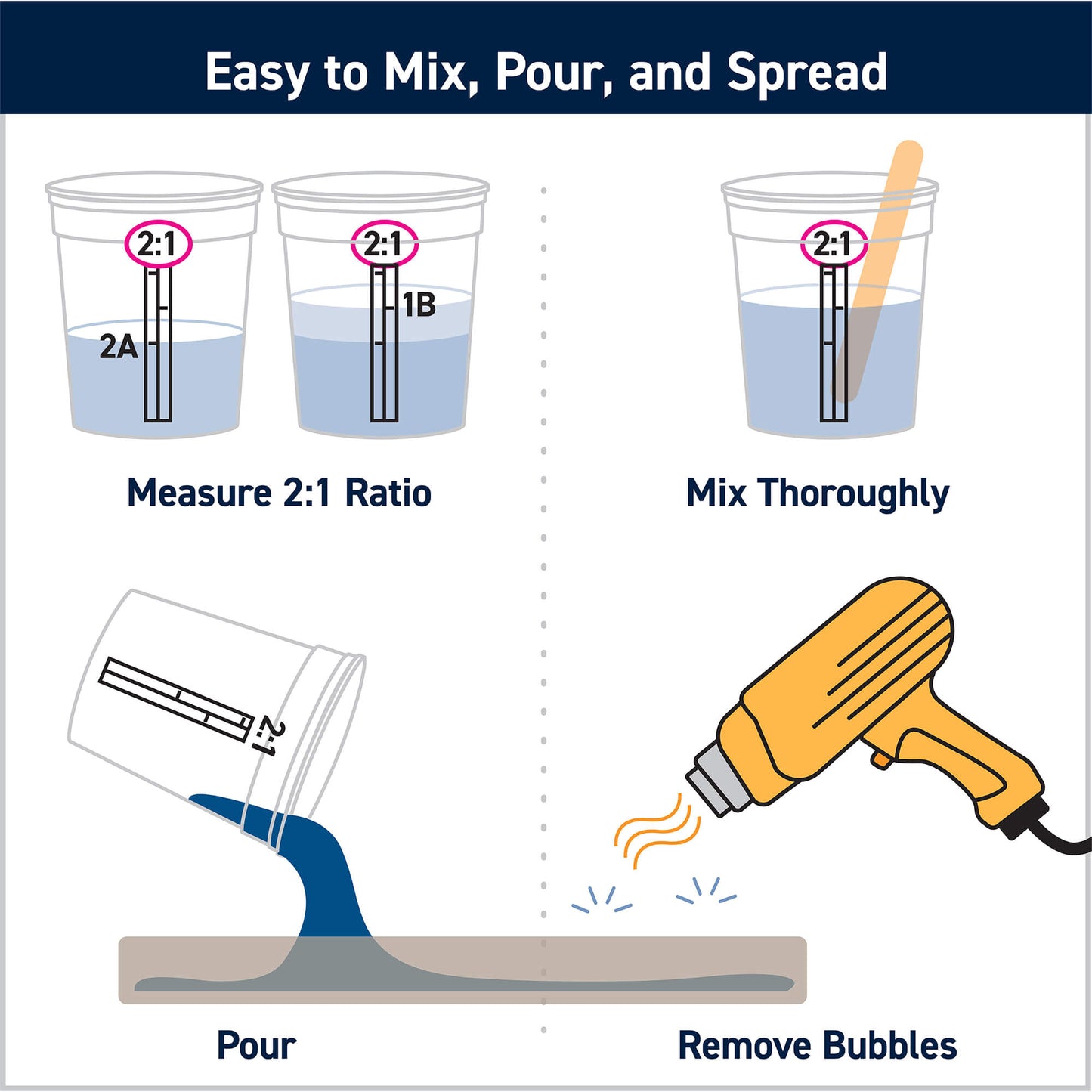

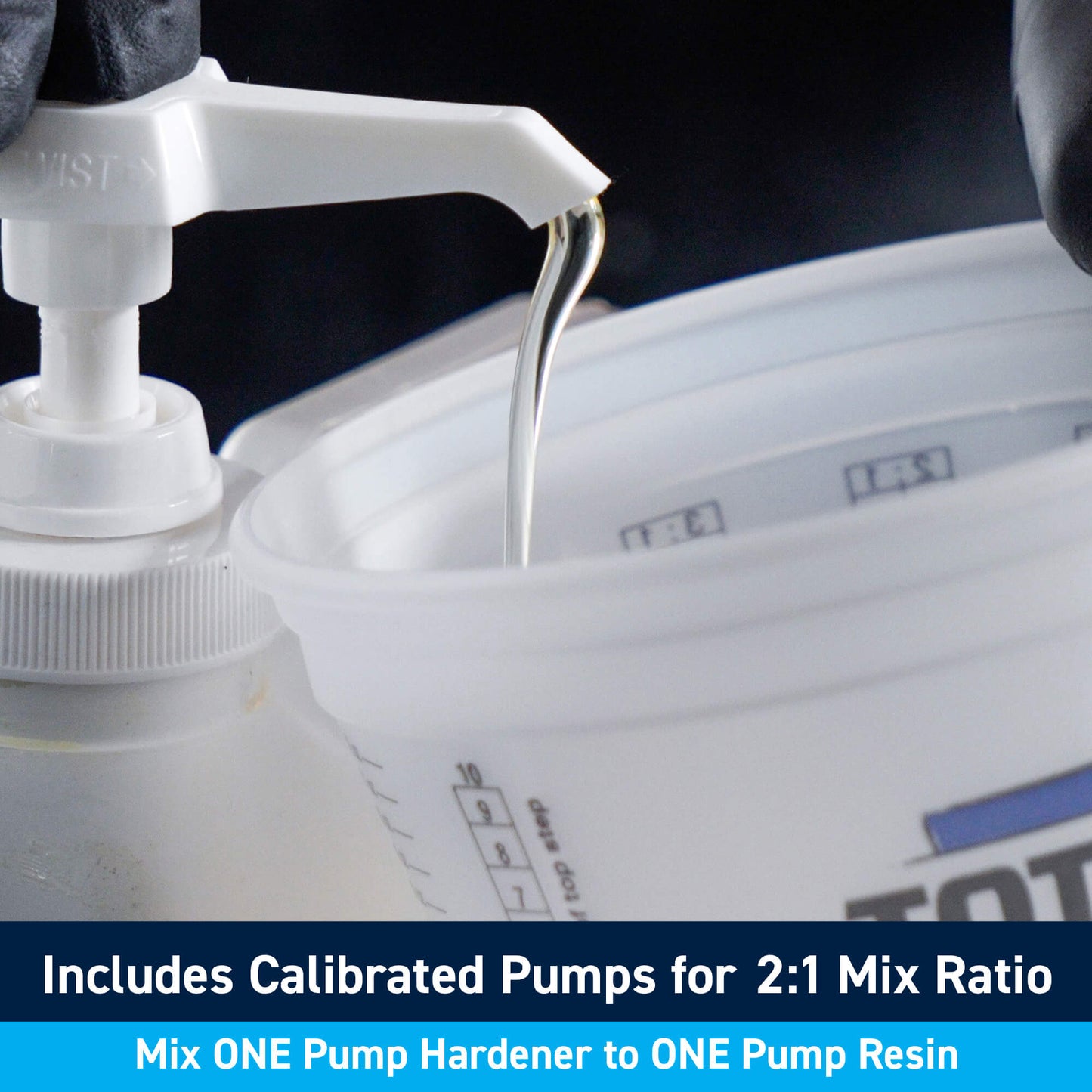

The calibrated pumps (included) and the simple 2:1 mix ratio of 2 parts resin to 1 part hardener makes it easy to get a perfect cure every time. If you use High Performance Epoxy frequently, our TotalBoat High Performance Epoxy Metering Pump Dispenser is pre-calibrated to the exact 2:1 ratio. So whether you need a little, or a lot, you’ll get the right ratio every time, without messes, spills, or waste.

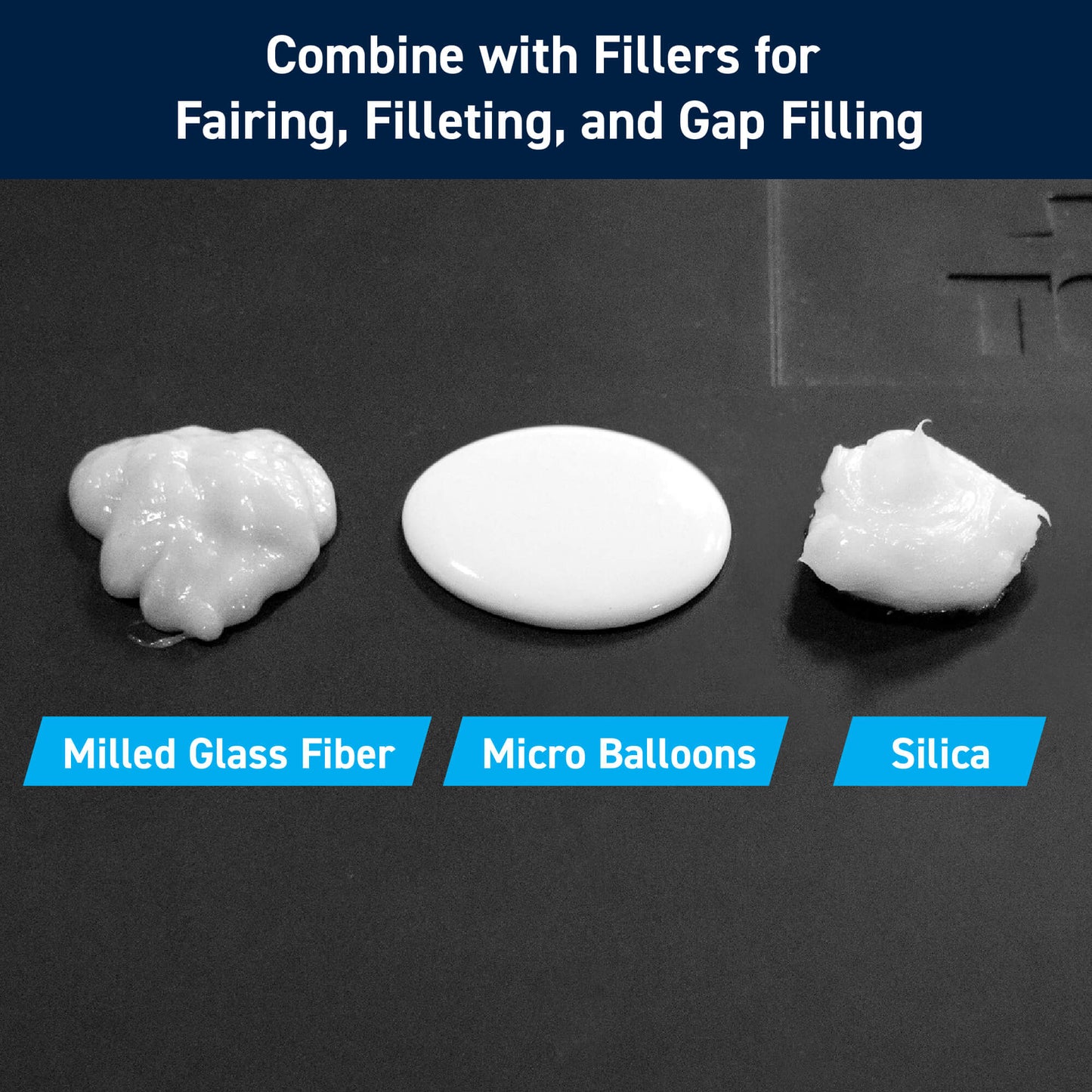

This versatile High Performance Resin Kit system can be used for so many different projects. Use unfilled for laminating, hand layups, coating, and vacuum bagging. Or, add TotalBoat fillers for a strong adhesive, filleting material, or fairing compound. So many capabilities at such a great value.

Cures to a high-gloss, ultra-clear finish — with no blush to scrub off between coats

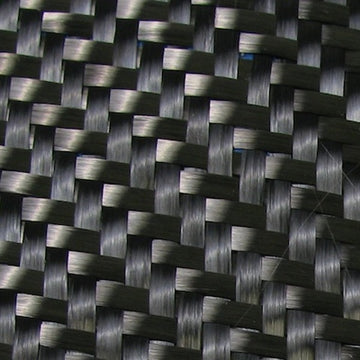

Its exceptionally clear, level finish is perfect for clear coating projects like showcasing carbon fiber's cool weave patterns, or for emphasizing wood's natural color, grain, and beauty. And, because there’s no amine blush, you won’t waste time on messy washdowns between coats, or worry whether you removed every trace of surface blush, so you can apply the next coat knowing it'll cure properly.

Three hardener speeds let you control working properties and cure times

With our High Performance Epoxy Resin, whether your goal is to buy more time or speed up the process, we make the choice easy by offering Fast, Medium, and Slow High Performance Hardeners that let you modify working properties and cure time to your advantage.

If you want the fastest cure and shortest pot life, or if you’re working in cooler temperatures, use the High Performance Fast Hardener. For most common applications, use the High Performance Medium Hardener. If you’re working in warm conditions, or you need a longer working time, use the High Performance Slow Hardener. Likewise if you’re new to using epoxy resin, you may find the extended pot life and cure time helpful.

All of its 'lows' are its high points

- Low 2:1 mix ratio makes it very easy to measure precisely for a proper mix and a reliable cure.

- Low viscosity flows easily to saturate the fibers in composite fabrics for better hand layups and vacuum bagging projects. Excellent thin-film characteristics provide smooth flow-out and self-leveling ideal for coating and laminating.

- Low drip properties ensure smooth and strong coating, laminating, and bonding, and it cures with very low shrinkage.

- Low VOC content and low odor make it more suitable for shop or garage use where indoor air quality is especially important.

Which TotalBoat High Performance Kit Speed Should I Choose?

High Performance Fast Kit – Use the High Performance Fast Kit for the fastest cure and shortest working time at room temperature, or for an overnight cure in low temperatures (minimum 55°F).

High Performance Medium Kit – Use the High Performance Medium Kit for most common applications, or for an overnight cure at room temperature (77°F).

High Performance Slow Kit – Use the High Performance Slow Kit for extended working time and cure time at room temperature, or when working in warmer temperature conditions.

Not sure how much High Performance Epoxy you need? If you are using it to coat a surface, try our simple epoxy calculator to determine how much resin your project will require.

High Performance Epoxy Kit Details

- Kit options include 1.5-pint, 1.5-quart, 1.5-gallon, or 3-gallon quantities of High Performance Epoxy Resin, with your choice of High Performance Fast, Medium, and Slow Hardeners so you can adjust working and cure times. NOTE: 1.5-Pint Kit is only available with slow hardener.

- Premium, high-performance epoxy resin has a naturally clear, glossy, level finish when cured.

- Cures with greater clarity and more flexibility than traditional 5:1 epoxy systems.

- Low viscosity is ideal for coating, laminating, hand layups, & vacuum bagging applications.

- Combine with fillers for a high-strength bonding, gluing, filleting, or fairing compound.

- Bonds readily with fiberglass and other composite fabrics, wood, aluminum, steel, and lead

- Cured epoxy surface is BPA-free, safer for potential food contact.

- Easy to measure in a 2:1 mix ratio with non-blushing TotalBoat High Performance Fast, Medium, or Slow Hardeners.

- Measure precise 2:1 ratio with the calibrated 2:1 Epoxy Pumps (included), or manually by weight or volume.

- Compatibility: Do not use the High Performance Epoxy Resin and High Performance Hardener interchangeably with the epoxy resin and hardener from other 2:1 epoxy systems.

- Kit Sizes: Groups Size M – 1.5 Pint Kit (great for small projects), Group Size A – 1.5 Quart Kit, Group Size B – 1.5 Gallon Kit, Group Size C – 3 Gallon Kit (a great value for bigger projects)

- Kit Speeds: Slow, Medium, Fast

- Kit Contents for 1.5 Quart, 1.5 Gallon, & 3 Gallon Kits: TotalBoat High Performance Epoxy Resin, TotalBoat High Performance Hardener (Slow, Medium, or Fast), calibrated 2:1 measuring pumps & instructions, and 2 quart size plastic mixing pots.

- Kit Contents for 1.5 Pint Kit: TotalBoat High Performance Epoxy Resin, TotalBoat High Performance Slow Hardener, and 2 pint size plastic mixing pots. PINT KITS DO NOT INCLUDE PUMPS

| Group Size / Speed | High Performance Epoxy Resin Quantity | High Performance Hardener Quantity | Mixed Quantity |

| M / Slow | 16.0 fl. oz. | 8.0 fl. oz | 24.0 fl. oz |

| A / Slow | 31.8 fl. oz. | 15.2 fl. oz | 47.0 fl. oz |

| A / Medium | 31.8 fl. oz. | 15.4 fl. oz. | 47.2 fl. oz |

| A / Fast | 31.8 fl. oz. | 17.9 fl. oz. | 49.7 fl. oz |

| B / Slow | 127.2 fl. oz. | 63.8 fl. oz. | 191.0 fl. oz. (1.5 gallons) |

| B / Medium | 127.2 fl. oz. | 62.9 fl. oz. | 190.1 fl. oz. (1.5 gallons) |

| B / Fast | 127.2 fl. oz. | 62.6 fl. oz. | 189.8 fl. oz. (1.5 gallons) |

| C / Slow | 254.4 fl. oz. | 127.7 fl. oz | 382.1 fl. oz. (3 gallons) |

| C / Medium | 254.4 fl. oz. | 127.4 fl. oz. | 381.8 fl. oz. (3 gallons) |

| C / Fast | 254.4 fl. oz. | 128.2 fl. oz. | 382.6 fl. oz. (3 gallons) |

| Properties (Admixed) | High Performance Fast Hardener | High Performance Medium Hardener | High Performance Slow Hardener |

| Color | Clear/Amber | Clear | Clear |

| Mix Ratio by Volume (Resin:Hardener) | 2:1 | 2:1 | 2:1 |

| Mix Ratio by Weight (Resin:Hardener) | 100A:46B | 100A:45B | 100A:45B |

| Gel Time at 77°F (150g mass) | 10 min. | 25 min. | 40 min. |

| Tack-Free Time at 77°F | 2 hrs. | 3 hrs. | 5 hrs. |

| Full Cure at 77°F | 2 days | 3.5 days | 5 days |

| Minimum Recommended Temperature | 55°F | 55°F | 55°F |

| Tensile Strength | 7,700 psi | 8,000 psi | 7,300 psi |

| Tensile Modulus | 380,000 psi | 390,000 psi | 360,000 psi |

| Tensile Elongation | 7.5% | 7.0% | 6.7% |

| Flexural Strength | 11,600 psi | 11,600 psi | 10,200 psi |

| Flexural Modulus | 330,000 psi | 360,000 psi | 330,000 psi |

| Compressive Strength | 9,500 psi | 9,900 psi | 8,900 psi |

| Volumetric Shrinkage | 4.4% | 4.4% | 3.1% |

| Hardness, Shore D | 84 | 83 | 83 |

| Intended for Clear Coating Applications? | YES | YES | YES |

| Maximum Pour Depth, Per Layer** | Less than 1/8" | 1/8" |

|

**NOTE: For 2:1 Slow Hardener maximum pour depth: Helping to dissipate heat from the cure will generally promote a more clear, smooth surface. If heat is not allowed to dissipate sufficiently from a mold or casting, it is still possible for pours, even with these guidelines, to generate enough heat to leave an imperfect surface or a slight yellow cast in the cured product.

FREQUENTLY BOUGHT TOGETHER

TECHNICAL DATA

- Application Method: Brush, Roller, or Syringe; can also be poured and spread with an epoxy spreader

- Minimum Recommended Application Temperature: 55°F (for ALL hardeners)

- Recommended Temperature for Dispensing by Pumps: 60-70°F

- Safety Information: Work in a well-ventilated area and wear protective eye wear, protective clothing, and suitable gloves

- High Performance Epoxy Resin Color: Clear

- High Performance Slow Hardener Color: Clear

- High Performance Medium Hardener Color: Clear

- High Performance Fast Hardener Color: Clear/amber

- Mix Ratio by Volume: 2A:1B (2 parts epoxy resin to 1 part hardener)

- Thinner: Do not thin this product

- Surface Prep Solvent: Denatured alcohol or acetone (only for use on compatible substrates)

- Cleanup: Part A – EPOXY RESIN: Denatured alcohol, acetone, vinegar

- Cleanup: Part B – HARDENER: Warm, fresh water and a mild soap, or denatured alcohol

- Cleanup: Mixed Epoxy: Scrape up and remove any uncured material, as needed. Denatured alcohol, lacquer thinner, or acetone may be used to clean up uncured, mixed epoxy. Cured epoxy must be removed mechanically.

-

Clear High Performance Epoxy Kits

- Best for:

- Cured color:

- Mix ratio by volume:

- Mix ratio by weight:

- Maximum pour depth per layer:

- Application temperature/RH:

- Working time:

- Full cure time:

- BPA free?

- UV resistant?

- Units of measure:

- THIS ITEM

-

Clear High Performance Epoxy Kits

- Best for: Boat building and repairs, glassing projects & clear coating applications

- Cured color: With 2:1 Slow Hardener - Clear; 2:1 Medium Hardener - Clear; 2:1 Fast Hardener - Clear/light amber

- Mix ratio by volume: 2A:1B

- Mix ratio by weight: With 2:1 Slow Hardener - 100A:45B; 2:1 Medium Hardener - 100A:45B; 2:1 Fast Hardener - 100A:46B

-

Maximum pour depth per layer:

• 2:1 Slow Hardener - 1/4", up to 75°F, for larger pours, slabs; 1/8", over 75°F, for larger pours, slabs; 3/8", up to 75°F, for smaller castings using up to 1 oz. of epoxy; 1/4", over 75°F, for smaller castings using less than 4 oz. of epoxy

• 2:1 Medium Hardener - 1/8"

• 2:1 Fast Hardener - Less than 1/8" - Application temperature/RH: Minimum of 55°F, 0-90% RH

- Working time: With 2:1 Slow Hardener - 20-45 minutes @ 77°F; 2:1 Medium Hardener - 10-30 minutes @ 77°F; 2:1 Fast Hardener - 5-15 minutes @ 77°F

- Full cure time: With 2:1 Slow Hardener - 5-7 days @ 77°F; 2:1 Medium Hardener - 3-5 days @ 77°F; 2:1 Fast Hardener - 2-5 days @ 77°F

- BPA free? Yes

- UV resistant? No

- Units of measure: 1.5 Pint Kit, 1.5 Quart Kit, 1.5 Gallon Kit, 3 Gallon Kit

-

Traditional 5:1 Marine Epoxy Resin Kits

- Boat building and repairs, fiberglass projects & marine composites

- Clear/amber

- 5A:1B

- 100A:18B

- Less than 1/8"

- 5:1 Slow Hardener - minimum 60°F; 5:1 Fast Hardener - minimum 40°F; 0-90% RH

- 5:1 Slow Hardener - 20-45 minutes @ 75°F; 5:1 Fast Hardener - 10-25 minutes @ 75°F

- 3-5 days @ 75°F

- • 5:1 Slow Hardener IS NOT BPA free

• 5:1 Fast Hardener is BPA free - No

- Quart Kit, Gallon Kit, 4.5 Gallon Kit

-

TableTop Epoxy Resin Kits

- Coating table tops and bar tops with a high-gloss finish; Small castings with a pour depth up to 1"

- Clear

- 1A:1B

- 1.2A:1B

- 1/8" - 1/4"

- 70°F to 80°F, 0-85% RH

- 40 minutes @ 77°F

- 5-7 days

- Yes

- Yes - For superior UV protection, coat with UV-blocking varnish.

- 2 Quart Kit, Gallon Kit, 2 Gallon Kit, 4 Gallon Kit

-

Artist Epoxy Resin Kit

- Casting molds for jewelry, coasters, and displays; Coating canvas, tumblers, and table tops; Creating ocean waves, geodes, marbling, and other techniques

- Clear

- 1A:1B

- 1.11A:1B

- 1/4" for flood coatings; up to 2" for smaller castings using less than 10 oz. of epoxy

- 65-75°F, 0-60% relative humidity

- 30 minutes

- 3-5 days

- Yes

- Yes

- 8 Oz. Kit, 16 Oz. Pint Kit, 32 Oz. Quart Kit, 128 Oz. Gallon Kit, 256 Oz. 2-Gallon Kit

YOU MAY ALSO LIKE

Frequently Asked Questions

-

What is the difference between High Performance and Traditional 5:1 epoxy resin kits?

High Performance Epoxy is clear and more flexible when cured than the Traditional 5:1 Epoxy system, which has higher tensile strength and stiffness. Both systems are used for boat building and repair, composite laminating, bonding, fairing and filleting, but because of its clear color, the High Performance system is also ideal for clear coating applications in wooden boat builds, shallow castings in epoxy river tables, woodworking and art projects.

Each system has its own set of hardeners: High Performance has fast, medium, and slow hardener; the 5:1 system has fast and slow hardeners. Finally, when the 5:1 system cures, the surface is coated with amine blush, a waxy byproduct that must be washed off before additional coatings are applied. The High Performance Epoxy system is practically blush-free. -

Which TotalBoat High Performance Hardener should I use?

Use High Performance Fast Hardener for the fastest cure and shortest working time at room temperature, or for an overnight cure in low temperatures (minimum 55°F).

Use High Performance Medium Hardener for most common applications, or for an overnight cure at room temperature (77°F).

Use High Performance Slow Hardener for extended working time and cure time at room temperature, or when working in warmer temperature conditions. -

Does this epoxy dry clear?

When High Performance Epoxy Resin is paired with its Slow or Medium Hardener, the resulting cured epoxy is extremely clear; when paired with its Fast Hardener, it may have a slight amber tone, but in most applications, this is not noticeable. Even if there is a tiny bit of amber color in the hardener, it’s minimized once the resin and hardener are mixed. In thin film applications, such as laminations, there won’t be enough material to show any amber tone. However, if absolute clarity is required for a specific application, Slow or Medium Hardener might be a more suitable choice. -

What does “blush-free” mean?

Amine blush is a waxy substance that forms on the surface as epoxy cures. It can interfere with the adhesion of additional coatings, so it must be removed gently with warm water and a Scotch-Brite pad. Blush is present in all epoxies but its content in clear epoxy is extremely low. Even so, it’s possible small pockets of blush can collect on the surface so it’s considered best practice to wash the surface with warm water and a Scotch-Brite pad prior to sanding. -

Is High Performance Epoxy Resin UV resistant?

Most epoxies have poor UV resistance and must be coated with varnish, a polyurethane clear coat, or other UV stable coating. -

Is High Performance Epoxy Resin food safe after it’s cured?

This epoxy is BPA-free, and is considered safe for indirect contact with food, once cured. -

How do I apply High Performance Epoxy?

Application method varies by project type. You can apply using a spreader, syringe, or roller. For shallow casting, pour at a maximum thickness of 1/8th – 1/4th inch depth, per layer. Pour multiple, shallow layers, for best results. -

Can I use High Performance Epoxy in cold weather?

Yes, but cold temperatures make the viscosity of resin and hardeners increase and may require more force to pump thicker materials. Excessive force on either one of the plunger heads may also cause the pumps to break. Dispensing material at 60-70°F is recommended for optimal pump performance. -

What are the ideal working conditions?

Epoxy is very sensitive to application temperatures. The minimum recommended temperature for all hardeners is 55°F. The recommended temperature for dispensing via pump is 60-70°F. -

What is the working time of the High Performance Epoxy?

10 minutes for fast hardener, 25 minutes for medium hardener, and 40 minutes for slow hardener. -

What is the recoat time of this resin system?

You can recoat once it tacks up a little, about 25 minutes at 77 degrees. -

What is the mix ratio of this epoxy by weight?

When using Fast Hardener: 100A:46B. When using Medium Hardener: 100A:45B. When using Slow Hardener: 100A:45B. The first number is the amount of epoxy resin; the second number is the amount of hardener. -

Do I need to sand epoxy between coats?

Light sanding is recommended, followed by an oil-free solvent wipe or a clean cloth moistened with either isopropyl alcohol or plain water to remove dust. -

How should I prepare this epoxy for primer after sanding?

After the epoxy has cured, wash with warm water just in case there is any amine blush, sand smooth and wipe the surface with a clean, lint-free rag dampened with acetone or denatured alcohol. -

Will epoxy still cure if mixed at an incorrect ratio?

No, unlike polyester resin, epoxies require a very specific resin to hardener ratio in order to cure properly. You will need to remove the epoxy and start over. Solvents like acetone may be used to remove the uncured resin. -

Can I leave the pumps in the resin containers?

Yes, you can leave the pumps on in the resin and hardener containers when not in use for a few weeks, but for longer-term storage, we recommend that you pull the pumps out, clean them, and put the original caps on the resin and hardener containers. -

Can this epoxy resin be thinned?

We don’t recommend thinning High Performance Epoxy with any type of solvent, because solvents can drastically change the properties of the epoxy. Heating the resin slightly is the best way to thin it because it makes the epoxy more workable, without changing the chemical composition. -

How many square feet will one-gallon of mixed epoxy cover?

When poured as a coating or for sealing a surface, one gallon of mixed epoxy yields approximately 25.6 square feet at 1/16" thickness, 12.8 square feet at 1/8" thickness, and 6.4 square feet at 1/4" thickness. More information on epoxy coverage can be found in this epoxy coverage guide. -

Is this resin compatible with fillers?

Yes, this epoxy system can be used with various fillers to thicken it for bonding, fairing, filling, and filleting. It can be mixed with fillers such as colloidal silica (also known as silica thickener), milled glass fiber, wood flour, or microballoons. Add fillers after epoxy resin and hardener are mixed thoroughly. More information on epoxy fillers can be found in our blog.