FOR FAIRING AND COSMETIC REPAIRS

HIGH-BUILD, FAST CURE FORMULA

EASY TO SPREAD

EASY TO SAND

Polyester Fairing Compound

Polyester Fairing Compound

FOR FAIRING AND COSMETIC REPAIRS

HIGH-BUILD, FAST CURE FORMULA

EASY TO SPREAD

EASY TO SAND

Couldn't load pickup availability

Versatile filler and fairing compound with many applications

From boat building and repairs to automotive applications, there are many uses for this versatile fairing material, including:

- Fairing fiberglass decks and hulls (above the waterline only)

- Cosmetic filling on composite surfaces to repair shallow dings, cracks, dents, and gouges

- Repairing fiberglass parts, molds, and plugs

- Filling print-through or porosity on composite surfaces

- Fairing joints in sheet metal

TotalBoat Polyester Fairing Compound can also be tinted to better match existing gelcoat. Just be sure to use colorants that are safe for polyester resins.

Economical, time-saving alternative for composite tooling and repair applications

TotalBoat Polyester Fairing Compound & Marine Filler is not only less expensive than epoxy fairing compounds, it’s also chemically compatible with polyester resins, and can create strong primary bonds when used to fair polyester resin layups. It also bonds chemically to gelcoat, for a stronger, longer-lasting finish. Polyester Fairing Compound’s quick setup time is also a plus because it greatly reduces the time between application and sanding, for quick turnaround, which is very important for composite shops with tight production schedules.

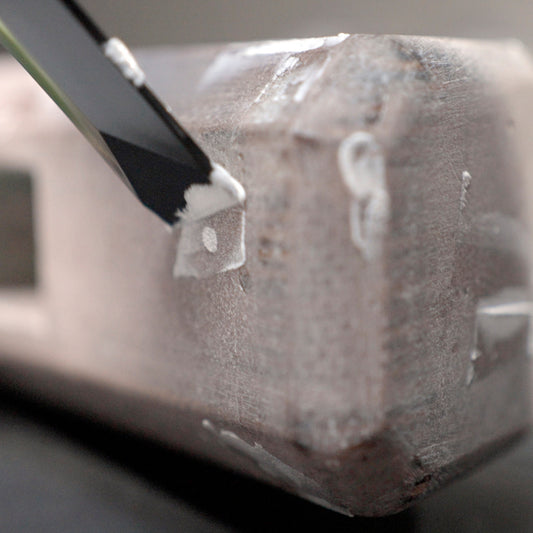

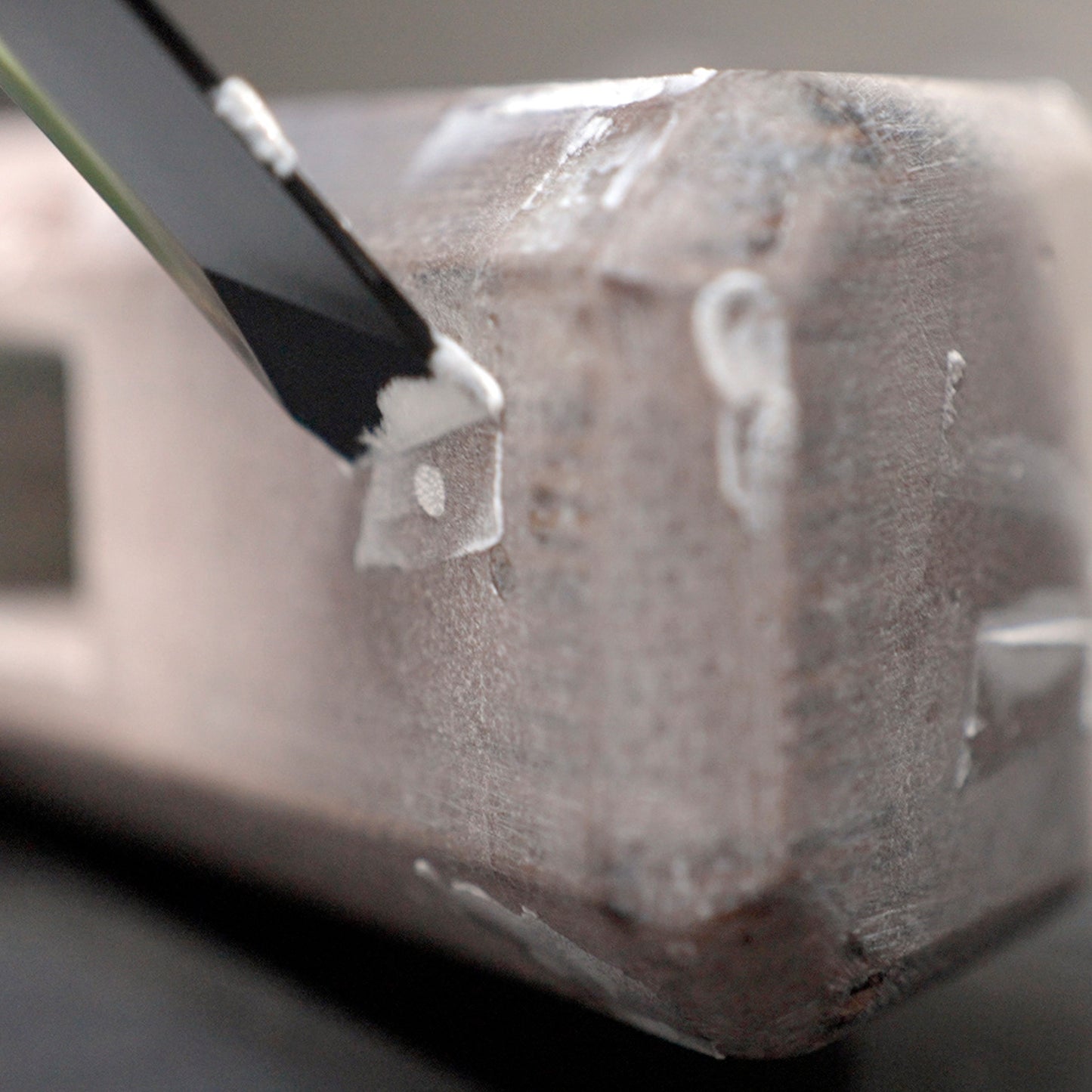

Smooth drag, no sag, and perfect feathering

Tooling professionals and those doing DIY repairs will appreciate Polyester Fairing Compound’s thick, buttery consistency that won’t sag on vertical and overhead surfaces. It spreads evenly, drags smoothly, and creates a perfect feathered edge the first time — every time — so no time is wasted on reapplication.

Quick setup time and very easy to sand

This lightweight cosmetic filler sets up quickly and can be sanded in as little as 30 minutes. It’s very easy to sand thick or thin areas to a perfectly smooth, streak-free surface, without tearing up the fine, feathered edge. It sands down to a powder, so it won’t load up, and you’ll use less sandpaper.

Polyester Fairing Compound Details

- Lightweight, 2-part polyester putty filler & fairing compound

- Use above the waterline on gelcoat, fiberglass/composite surfaces, and metals.

- Excellent workability, drags smoothly and evenly.

- Creates a feathered edge easily.

- Sets up quickly without sagging.

- Sand easily.

- Low styrene content for minimal shrinkage and less odor.

- Can be overcoated with paint, gelcoat, or barrier coat primer (if used below the waterline).

- Sizes: Quart, Gallon. Includes MEKP catalyst.

- Bonus: Each order includes 1 plastic spreader

- IMPORTANT: TotalBoat Polyester Fairing Compound is for use above the waterline only. If used below the waterline, it must be overcoated with a barrier coat such as TotalBoat TotalProtect Epoxy Barrier Coat Primer.

Important Safety Precautions

Always wear protective clothing and equipment to protect your eyes, skin, and lungs when working with or sanding TotalBoat Polyester Fairing Compound. Personal protective clothing should include appropriate protective gloves, safety glasses or goggles, a proper respirator, and a proper apron or similar protective clothing. Keep away from heat, hot surfaces, sparks, open flames, and other ignition sources. No smoking. Only use outdoors or in a well-ventilated area. Store in a cool, well-ventilated place (below 75°F). Do not handle until all safety precautions have been read and understood.

FREQUENTLY BOUGHT TOGETHER

SEE HOW EASY IT IS TO USE POLYESTER FAIRING COMPOUND

SEE HOW EASY IT IS TO USE POLYESTER FAIRING COMPOUND

TECHNICAL DATA

- Application Temperature: 60-90°F

- Working/Cure Times: Variable. At 77°F, adding 14-16 drops of MEKP to one ounce of TotalBoat Polyester Fairing Compound will provide a working time of 10-15 minutes, and will cure in 20-30 minutes.

- Dry time to sand: Dependent on temperature, amount of catalyst, and mass of TotalBoat Polyester Fairing Compound. Example: 20-30 minutes for a 100g mass catalyzed with 1% MEKP @ 77°F

- IMPORTANT APPLICATION NOTE: This lightweight polyester cosmetic marine filler is primarily for use in tooling and repair applications as a fairing material only. It’s not designed for structural repairs requiring strength and dimensional stability. For structural repairs, you can use TotalBoat Polyester Structural Repair Putty, a high-strength, fiber-reinforced polyester putty for filling larger cracks & voids. After it cures, apply TotalBoat Polyester Fairing Compound on the repaired area, allow to cure, then sand to achieve an extremely smooth surface ready for paint or gelcoat.

- Shelf Life: Polyester resins have a limited shelf life and will, over time, harden in the container without the addition of catalyst. Shelf life is dependent on a number of factors such as product formulation and storage conditions. As a general rule, the shelf life for uncatalyzed polyester resins should be up to 6 months when stored in dry, cool conditions below 70°F. Warm to above 60°F before use.

-

Polyester Fairing Compound

- Best for:

- Composition:

- Substrates:

- Mix ratio:

- Mixed/cured color:

- Application methods:

- Application temperature/RH:

- Working time:

- Sandable time:

- Finish/topcoat with...

- UV resistant?

- BPA free?

- Units of measure:

- THIS ITEM

-

Polyester Fairing Compound

- Best for: Fairing fiberglass decks and hulls (above the waterline only); cosmetic filling on composite surfaces to repair shallow dings, cracks, dents, and gouges; repairing fiberglass parts, molds, and plugs; filling print-through or porosity on composite surfaces; fairing joints in sheet metal

- Composition: Polyester resin-based fairing compound

- Substrates: Fiberglass, gelcoat, composites, sheet metal

- Mix ratio: For a proper cure, add 1-2% MEKP catalyst (included) to fairing compound.

- Mixed/cured color: Off White

- Application methods: Spreader, Trowel

- Application temperature/RH: 50-95°F; 0-90% RH

- Working time: Variable. At 77°F, adding 14-16 drops of MEKP to one ounce of TotalBoat Polyester Fairing Compound will provide a working time of 10-15 minutes, and will cure in 20-30 minutes.

- Sandable time: Depends on temperature, amount of catalyst, and mass of fairing compound. Example: 20-30 minutes @ 77°F for a 100g mass catalyzed with 1% MEKP.

- Finish/topcoat with... For UV protection, TotalBoat Polyester Fairing Compound must be finished with gelcoat, or primed and painted. For underwater applications where this fairing compound may be exposed to water, always barrier coat with TotalBoat TotalProtect, to prevent water intrusion.

- UV resistant? No

- BPA free? No

- Units of measure: Quart Kit, Gallon Kit

-

Polyester Structural Marine Repair Putty

- Joining and filleting fiber-reinforced plastic (FRP) parts, bonding dissimilar materials such as metal and wood, radius forming, filling larger voids and cracks in composites, and fabricating composite parts

- Polyester resin-based repair putty

- FRP composites, core materials, wood

- Add 1-2% MEKP catalyst (included) to repair putty.

- Blue

- Spreader, Trowel

- 50-95°F; 0-90% RH

- For a 100g mass, catalyze with 1% MEKP for approximately 15-20 minutes of working time at 70°F (14 drops of MEKP catalyst per ounce of structural repair putty).

- For applications where this product will not be laminated over, a polyester resin air dry solution can be added at the rate of 1 ounce per quart of putty before catalyzing.

- Gelcoat with wax, Polyester Finishing Resin

- No

- No

- Quart Kit, Gallon Kit

-

TotalFair Epoxy Fairing Compound

- Reshaping, filling, fairing for boat building and repairs

- Epoxy-based fairing compound

- Fiberglass, wood, aluminum, steel, and previously applied epoxy products or two-component urethanes in good condition

- 1A:1B

- Green

- Spreader, Trowel

- 50-100°F

- 150g mass, minimum - 15-20 minutes @ 90°F; 30 minutes @ 70°F; 45-60 minutes @ 50°F

- 3 hours @ 90°F; 6-8 hours @ 70°F; 12 hours @ 50°F

- Paint, primer, epoxy primer, or more TotalFair. DO NOT apply gelcoat directly to TotalFair. It will not cure properly. Before applying gelcoat, overcoat TotalFair with an epoxy barrier coat or epoxy surfacing primer.

- No

- No

- 2 Pint Kit, 2 Quart Kit, Gallon Kit

-

FixWood Wood Repair Epoxy Putty

- High-strength, waterproof, permanent repairs to rotted or damaged wood

- Epoxy-based putty

- Wood

- 1A:1B

- Tan

- Shape by hand or using tools.

- 50-100°F

- 30-35 minutes @ 72°F

- Less than 6 hours @ 72°F

- Stain it or coat it with 1-part or 2-part polyurethane paint or varnish.

- No

- No

- 2 Pint Kit, 2 Quart Kit

YOU MAY ALSO LIKE

FREQUENTLY ASKED QUESTIONS

-

What applications is Polyester Fairing Compound most appropriate for?

This lightweight marine filler & fairing compound is ideal for repairing cosmetic dents, dings, and scratches in fiberglass and gelcoat. There are many uses for this fairing material, including fairing fiberglass decks and hulls (above the waterline only), fairing joints in sheet metal, and cosmetic filling on composite surfaces. -

Can it be used over epoxy?

Yes, it is suitable for light fairing over epoxy, but the surface must be sanded first to create a mechanical bond. -

Can this be used over cured polyester resin?

Yes, be sure to sand first, and remove sanding residue. -

Can polyester fairing compound be applied over epoxy primer?

Yes, sand primer first with 80 grit, wipe down with acetone to remove any residue, then apply. -

Can it be used on a two-part, epoxy-based paint to repair chipping or cracks?

An epoxy based fairing compound would be more appropriate. Remember that fairing compounds do not provide UV protection, and are not finishes. They must be primed and painted over. -

Can polyester fairing compounds be used below the waterline?

It is recommended for use above the waterline only. An epoxy barrier coat primer should be used over any applications below the waterline. -

Can fairing compound be used for structural repairs?

This product is intended for fairing minor cosmetic surface defects before applying gelcoat or paint, as it is easy to sand to a feather edge once dry. It is not intended for structural or load-bearing repairs like floors or transoms. For structural repairs requiring strength and dimensional stability, you can use TotalBoat Polyester Structural Repair Putty, a high-strength, fibrous polyester putty for filling larger cracks and voids. -

What else should I know before choosing Polyester Fairing Compound?

This product can be tinted to better match existing gelcoat colors. Be sure to use colorants that are compatible with polyester resins. For UV protection, it must be finished with gelcoat, or primed and painted. For underwater applications or where Polyester Fairing Compound & Marine Filler may be exposed to water, barrier coat with TotalProtect to prevent water intrusion. -

What is the recommended surface preparation before fairing?

Remove all dirt, dust, grease, oil, wax, or amine blush from the surface. For fine fairing applications, sand the substrate with 100-180 grit sandpaper Use an air hose to remove all sanding residue. For larger areas and deeper crevices, sand the area with 60-80 grit sandpaper and remove all sanding residue. Wipe away any remaining residue and contaminants with a clean, lint-free, cotton rag wetted with acetone. -

How much MEKP catalyst should I use? What is the working time?

At 77°F, adding 14-16 drops of MEKP to one ounce of TotalBoat Polyester Fairing Compound & Marine Filler will provide a working time of 10-15 minutes, and will cure in 20-30 minutes. Keeping catalyzed material in a larger mass will shorten the working time. -

How long do I have to wait before sanding?

It is dependent on temperature, amount of catalyst, and mass of TotalBoat Polyester Fairing Compound. For example, it would be 20-30 minutes for a 100g mass catalyzed with 1% MEKP at 77°F. -

What is the shelf life of Polyester Fairing Compound?

Polyester resins have a limited shelf life and will, over time, harden in the container without the addition of catalyst. As a general rule, the shelf life for uncatalyzed polyester resins is up to 6 months when stored in dry, cool conditions below 70°F. Warm to above 60°F before use.