STRONG, PERMANENT REPAIRS

Restores rotted or damaged wood easily. Machine or fasten, once cured.EASY TO USE, EASY TO SAND

Simple 1A:1B mix ratio. Shape using tools or by hand. Easy to sand, once cured.STAIN OR PAINT

Can be stained or painted to match surrounding wood.100% WATERPROOF

Use indoors or outdoors.FixWood Wood Repair Epoxy Putty

FixWood Wood Repair Epoxy Putty

STRONG, PERMANENT REPAIRS

Restores rotted or damaged wood easily. Machine or fasten, once cured.EASY TO USE, EASY TO SAND

Simple 1A:1B mix ratio. Shape using tools or by hand. Easy to sand, once cured.STAIN OR PAINT

Can be stained or painted to match surrounding wood.100% WATERPROOF

Use indoors or outdoors.Couldn't load pickup availability

The permanent cure for wood gone bad — or just plain gone

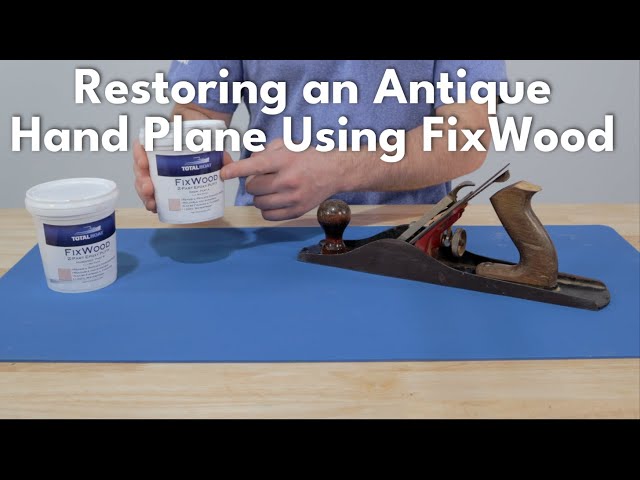

Dry rot, dings, dents, chips, and gouges are real eyesores. The thought of repairing rotted wood, restoring damaged wood that has historical significance, or attempting to remove & replace missing wood that’s irreplaceable can be daunting. If removing the bad wood just isn’t an option or finding a replacement for missing wood just isn’t possible, use TotalBoat FixWood marine-grade wood repair epoxy putty wood filler to repair it in place — fast, and for good.

Puts fast, easy repairs in the palms of your hands

TotalBoat FixWood has no VOCs or obnoxious odors, but you do need to wear latex or nitrile gloves to protect your hands while working with it. Just knead equal amounts of resin and hardener together until the mixture is a light tan color, with no streaks. Press the mixed putty firmly into the damaged area to push out any air pockets, and overfill the cavity slightly so you can sand the surface smooth after curing. To replace a missing piece of wood, sculpt the mixed putty in place by hand or with tools. The FixWood epoxy putty stays where you put it, without sagging, and retains its shape while curing. Once it’s cured, you can carve or grind it to refine the shape. Let your repair cure overnight then sand, if needed, and finish or fasten. If you want to blend the repair into the surrounding wood, just stain it or coat it with 1- or 2-part polyurethane paint or varnish.

Repairs are 100% waterproof and as strong or stronger than new in just a day, and can hold nails, screws, and other fasteners firmly.

FixWood Details

- 2-part, marine-grade, non-shrinking wood repair epoxy putty & wood filler

- High-strength repairs flex with the wood — no cracking or shrinkage.

- 100% waterproof, once cured

- Putty is easy to shape — no sagging or distortion.

- Very easy to sand.

- Can be stained or painted to match the surrounding wood type.

- Solvent-free formula has no VOCs or harsh fumes.

- For interior and exterior use above the waterline only.

- Mixed color: Tan

- Kit Sizes: 2-Pint, 2-Quart. Kits include equal amounts of resin and hardener.

Tip

If the wood is soft from dry rot, inject or apply TotalBoat Clear Penetrating Epoxy Sealer first to consolidate the wood. While the Penetrating Epoxy is still tacky, apply the mixed FixWood putty, as directed, and shape as desired.

Personal Safety Information

Wear protective gloves, clothing, and eye/face protection while using TotalBoat FixWood. Always wear protective gloves when kneading or shaping FixWood by hand. When sanding FixWood, wear protective gloves, protective clothing, face protection, and a proper respirator. Be sure to read and understand the instructions and the safety information in the Technical Data Sheet and Safety Data Sheet (SDS) before using this product.

FREQUENTLY BOUGHT TOGETHER

TECHNICAL DATA

- Application Method: Shape by hand or using tools

- Application Temperature: 50-100°F

- Working Time: 30-35 minutes @ 72°F

- Dry Time Before Sanding: <6 hours @ 72°F

- Dry Time to Overcoat: <6 hours @ 72°F

- Full Cure: 5-7 days @ 72°F

- Minimum Shelf Life: 1 Year

- Mixed Color: Tan

- Mix Ratio by Volume: 1A:1B (1 part Resin (Part A) to 1 part Hardener (Part B))

-

FixWood Wood Repair Epoxy Putty

- Best for:

- Composition:

- Substrates:

- Mix ratio:

- Mixed/cured color:

- Application methods:

- Application temperature/RH:

- Working time:

- Sandable time:

- Finish/topcoat with...

- UV resistant?

- BPA free?

- Units of measure:

- THIS ITEM

-

FixWood Wood Repair Epoxy Putty

- Best for: High-strength, waterproof, permanent repairs to rotted or damaged wood

- Composition: Epoxy-based putty

- Substrates: Wood

- Mix ratio: 1A:1B

- Mixed/cured color: Tan

- Application methods: Shape by hand or using tools.

- Application temperature/RH: 50-100°F

- Working time: 30-35 minutes @ 72°F

- Sandable time: Less than 6 hours @ 72°F

- Finish/topcoat with... Stain it or coat it with 1-part or 2-part polyurethane paint or varnish.

- UV resistant? No

- BPA free? No

- Units of measure: 2 Pint Kit, 2 Quart Kit

-

TotalFair Epoxy Fairing Compound

- Reshaping, filling, fairing for boat building and repairs

- Epoxy-based fairing compound

- Fiberglass, wood, aluminum, steel, and previously applied epoxy products or two-component urethanes in good condition

- 1A:1B

- Green

- Spreader, Trowel

- 50-100°F

- 150g mass, minimum - 15-20 minutes @ 90°F; 30 minutes @ 70°F; 45-60 minutes @ 50°F

- 3 hours @ 90°F; 6-8 hours @ 70°F; 12 hours @ 50°F

- Paint, primer, epoxy primer, or more TotalFair. DO NOT apply gelcoat directly to TotalFair. It will not cure properly. Before applying gelcoat, overcoat TotalFair with an epoxy barrier coat or epoxy surfacing primer.

- No

- No

- 2 Pint Kit, 2 Quart Kit, Gallon Kit

-

Polyester Fairing Compound

- Fairing fiberglass decks and hulls (above the waterline only); cosmetic filling on composite surfaces to repair shallow dings, cracks, dents, and gouges; repairing fiberglass parts, molds, and plugs; filling print-through or porosity on composite surfaces; fairing joints in sheet metal

- Polyester resin-based fairing compound

- Fiberglass, gelcoat, composites, sheet metal

- For a proper cure, add 1-2% MEKP catalyst (included) to fairing compound.

- Off White

- Spreader, Trowel

- 50-95°F; 0-90% RH

- Variable. At 77°F, adding 14-16 drops of MEKP to one ounce of TotalBoat Polyester Fairing Compound will provide a working time of 10-15 minutes, and will cure in 20-30 minutes.

- Depends on temperature, amount of catalyst, and mass of fairing compound. Example: 20-30 minutes @ 77°F for a 100g mass catalyzed with 1% MEKP.

- For UV protection, TotalBoat Polyester Fairing Compound must be finished with gelcoat, or primed and painted. For underwater applications where this fairing compound may be exposed to water, always barrier coat with TotalBoat TotalProtect, to prevent water intrusion.

- No

- No

- Quart Kit, Gallon Kit

-

Polyester Structural Marine Repair Putty

- Joining and filleting fiber-reinforced plastic (FRP) parts, bonding dissimilar materials such as metal and wood, radius forming, filling larger voids and cracks in composites, and fabricating composite parts

- Polyester resin-based repair putty

- FRP composites, core materials, wood

- Add 1-2% MEKP catalyst (included) to repair putty.

- Blue

- Spreader, Trowel

- 50-95°F; 0-90% RH

- For a 100g mass, catalyze with 1% MEKP for approximately 15-20 minutes of working time at 70°F (14 drops of MEKP catalyst per ounce of structural repair putty).

- For applications where this product will not be laminated over, a polyester resin air dry solution can be added at the rate of 1 ounce per quart of putty before catalyzing.

- Gelcoat with wax, Polyester Finishing Resin

- No

- No

- Quart Kit, Gallon Kit

YOU MAY ALSO LIKE