MAKES ALUMINUM PAINT STICK

Effective tie-coat primer ensures paint sticks stronger and lasts longer.EASY TO USE

Simple 3:1 mix ratio; easy to apply by brushing, rolling or spraying.MAXIMUM CORROSION PROTECTION

Barrier coat primer for aluminum boats, pontoons, and underwater metals.USE ABOVE OR BELOW THE WATERLINE

Compatible with all antifouling paints and other one- and two-part finishes.Aluminum Boat Barrier Coat Epoxy Primer

Aluminum Boat Barrier Coat Epoxy Primer

MAKES ALUMINUM PAINT STICK

Effective tie-coat primer ensures paint sticks stronger and lasts longer.EASY TO USE

Simple 3:1 mix ratio; easy to apply by brushing, rolling or spraying.MAXIMUM CORROSION PROTECTION

Barrier coat primer for aluminum boats, pontoons, and underwater metals.USE ABOVE OR BELOW THE WATERLINE

Compatible with all antifouling paints and other one- and two-part finishes.Couldn't load pickup availability

A sure-fire way to get paint to actually stick to your aluminum boat or pontoons

It’s a universal truth — you can’t just go slapping paint on aluminum and expect it to stick. You need to start with clean, bright, shiny, BARE aluminum that’s completely free of oxidation and surface contamination. It’s also really important to etch the aluminum surface just enough so the paint has something to cling to. We get it, so we developed TotalBoat Aluminum Boat Etch Wash and TotalBoat Aluminum Boat Barrier Coat. The etch wash cleans, conditions, brightens, and etches the surface to ensure excellent adhesion. The barrier coat primer prevents corrosion and provides superior adhesion for antifouling and other 1- and 2- part paints.

Provides excellent corrosion protection

Corrosion on metal boats and boat parts is a certainty. In saltwater and in warmer temperatures, even stainless steel is subject to crevice corrosion, which forms anywhere water can enter, but can’t exit, such as boat propeller and shaft assemblies. Crevice corrosion also eats aluminum alloys wherever there’s a juncture that lets saltwater enter, such as any place where objects are attached to the aluminum surface above or below the waterline.

The zinc chromate primers used previously have fallen out of favor for use under antifouling paints due to expense and environmental concerns, and you would never have applied them to underwater metals anyway because of galvanic corrosion. TotalBoat Aluminum Boat Barrier Coat prevents corrosion above and below the waterline effectively so your boat — and your paint job — will look better and last longer.

The simple 3 to 1 ratio is easy to mix accurately for optimum results

TotalBoat Aluminum Boat Barrier Coat is easy to mix and use. But if you’ve never applied a barrier coat before, you may want to start with a test batch to hone your technique. Just measure three parts base with one part curing agent in a paint pot. For example, use a graduated cup to measure 12 ounces of base to 4 ounces of hardener, and mix thoroughly. Accurate measuring is easy to do, and it’s important because with smaller amounts of base and curing agent, slight deviations in the mix ratio make a big difference. Don’t be intimidated by this, just be aware of it. Otherwise it’s easy to mix the entire batch at once. Simply pour the can of curing agent into the can of base. There’s enough room in there. No need to grab a separate container for mixing. To prevent waste, mix only the amount of Aluminum Boat Barrier Coat you think you can use before it kicks, which is 5 hours @ 70°F — a long time compared to other products.

Aluminum Boat Barrier Coat Details

- Durable, high-build barrier coat epoxy primer prevents corrosion on aluminum (and other metal surfaces)

- Safe for underwater metals such as props, shafts, keels, thru hulls, and trim tabs

- Can be used as a primer for any 1- and 2-part topside or antifouling paints

- Bonus: Each Gallon order includes a paint roller frame, 3/16 in. nap solvent-safe roller cover, metal tray, stir stick, and paint suit

- Apply to properly prepared aluminum and previously painted surfaces in good condition**

- Use above and below the waterline

- Fills small surface imperfections to dry smoothly and evenly

- Serves as an effective tie-coat primer so paints adhere strongly and last longer

- Two-part epoxy primer has an easy 3:1 mix ratio

- Easy to apply by brush, roller, or spray equipment

- Fast-drying, with no tedious sanding required

- Color: Available in Gray only

- Size: Quart Kit includes 1 quart Part A Base and ½ pint Part B Curing Agent

- Size: Gallon Kit includes ¾ gallon Part A Base and 1 quart Part B Curing Agent

- **IMPORTANT: Always test the previous paint to ensure it is not a 1-component paint

When etching and priming, timing is critical to success

Preparing, priming, and painting aluminum is definitely a DIY job, but there are a few timing factors you should know.

Applying Aluminum Boat Barrier Coat over (Optional) Aluminum Boat Etch Wash

After applying TotalBoat Aluminum Boat Etch Wash according to directions and drying the surface, you need to apply Aluminum Boat Barrier Coat within 1 hour of metal preparation, or aluminum oxide will form (yes, it happens that fast!), and the primer will not adhere properly.

Recoating Aluminum Boat Barrier Coat with Aluminum Boat Barrier Coat

Overcoat Aluminum Boat Barrier Coat with itself when the surface is thumbprint tacky—your thumbprint can be seen on the surface, but no epoxy sticks to your thumb. TotalBoat Aluminum Boat Barrier Coat can be recoated over itself for up to 60 days. If that time window is missed, sand with 80-grit sandpaper, and wipe the surface clean with a clean, lint-free cotton rag wetted with TotalBoat Dewaxer & Surface Prep and allow the solvent to evaporate completely. Recoat with Aluminum Boat Barrier Coat.

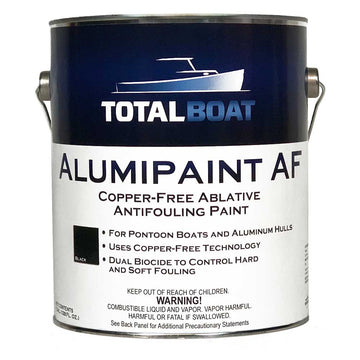

Overcoating Aluminum Boat Barrier Coat with Antifouling Bottom Paint

For best adhesion, use the ‘thumbprint’ method mentioned above. Overcoat with antifouling paint within the specified time window. If the specified overcoat window for antifouling paint is missed, wait 24 hours and sand with 80-grit sandpaper, then wipe the surface clean with TotalBoat Dewaxer & Surface Prep. Allow the solvent wipe to evaporate completely before applying any paint. TotalBoat AlumiPaint AF offers superior protection against fouling on aluminum hulls and pontoons. For underwater metals, apply TotalBoat Outdrive AF antifouling paint.

Overcoating Aluminum Boat Barrier Coat with Non-Antifouling or Topside Paint

Allow 48 hours for Aluminum Boat Barrier Coat to dry, then sand with 320-grit sandpaper. Remove sanding residue with TotalBoat Dewaxer & Surface Prep and let flash. Apply topcoat according to directions.

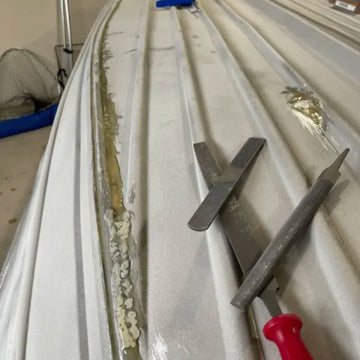

Note: Not meant to fill larger surface imperfections

High-build Aluminum Boat Barrier Coat can fill tiny scratches, but it’s not a filler. For scratches, deformations, dents, and dings 1⁄16” deep or greater, use TotalFair epoxy fairing putty first, then sand smooth and overcoat.

FREQUENTLY BOUGHT TOGETHER

TECHNICAL DATA

- Application Method: Brush: (natural bristle, solvent safe) Roll: (3/8" nap or foam solvent-safe roller cover) Spray: Conventional, airless, HVLP

- Application Temperature: 50-90ºF (0-85% RH)

- Induction Time: 15 minutes @ 70ºF. After mixing thoroughly, allow a 15-minute induction period before reduction (optional) and application.

- Pot Life: 2.5 hours @ 90°F, 5 hours @70°F, 10 hours @ 50°F

- Number of Coats: 2-3 (minimum) It's more important to ensure 8-12 mils of dry film thickness than a certain number of coats. More than three coats may be required based upon the application thickness.

- Film Thickness (per Coat): 4 mils dry (7 mils wet)

- Recommended Dry Film Thickness for a Barrier Coating: 8-12 mils

- Dry Time to Recoat (Aluminum Boat Barrier Coat over Aluminum Boat Barrier Coat): TotalBoat Aluminum Boat Barrier Coat can be recoated over itself for up to 60 days. If that time window is missed, sand with 80-grit sandpaper, and wipe the surface clean with a clean, lint-free cotton rag wetted with TotalBoat Dewaxer & Surface Prep, and allow the solvent to evaporate completely. Recoat with Aluminum Boat Barrier Coat.

- Dry Time to Overcoat (Antifoulant over Aluminum Boat Barrier Coat): 5-7 hours @ 75°F

- Dry Time to Overcoat (non-Antifouling Paint over Aluminum Boat Barrier Coat): WATER-BASED ANTIFOULING PAINT: Aluminum Boat Barrier Coat must be fully cured and sanded before applying any waterbased antifouling paint (including but not limited to TotalBoat JD Select, Pettit Hydrocoat, Interlux Bottomkote Aqua). SOLVENT-BASED ANTIFOULING PAINT: The ‘thumbprint’ method is the best for adhesion, and saves time. After applying the last layer of Aluminum Boat Barrier Coat, wait until it does not stick to your thumb, but you can make a thumbprint, or within the overcoat window — apply antifouling paint. If this window is missed, the surface must be sanded before applying paint. TEFLON™ OR VINYL PAINTS: When using Teflon or vinyl-based racing antifouling paints, Aluminum Boat Barrier Coat must be fully cured for 24 hours and sanded before applying antifouling paint.

- Dry Time to Launch (Minimum): : 12 hours @ 90ºF, 24 hours @ 70ºF, 5 days @ 50ºF

- Recommended Finish Coating: Ablative antifouling paint

- Color: Gray

- Finish: Matte

- Mix Ratio by Volume: 3:1 (3 parts base to 1 part curing agent)

- Theoretical Coverage (sq ft/gal): 225 (at 7 mils wet, not accounting for waste)

- VOC Content (g/L): 337 (Part A), 347 (Part B), 340 (Parts A and B admixed)

- Thinner: TotalBoat Epoxy Primer Thinner 200 (for brush, roller and spray applications)

- Surface Prep Solvent: TotalBoat Dewaxer & Surface Prep

- Cleanup Solvent: TotalBoat Epoxy Primer Thinner 200 or TotalBoat Dewaxer & Surface Prep

- Aluminum Etch (Optional): TotalBoat Aluminum Boat Etch Wash

-

Aluminum Boat Barrier Coat Epoxy Primer

- Best for:

- Primer type:

- Substrates:

- Above/below waterline:

- Suitable topcoats:

- Application methods:

- Number of coats:

- Thinner:

- Cleanup:

- Coverage:

- Application temperature/RH:

- Units of measure:

- THIS ITEM

-

Aluminum Boat Barrier Coat Epoxy Primer

- Best for: Corrosion protection and waterproofing/water barrier on aluminum and underwater metals

- Primer type: Barrier coat

- Substrates: Aluminum and previously painted surfaces in good condition (not 1-part paints)

- Above/below waterline: Above or below

- Suitable topcoats: Antifouling paints, topside paints, and urethanes

- Application methods: Brush: (natural bristle, solvent safe); Roll: (3/8" nap or foam solvent-safe roller cover); or Spray: Conventional, airless, HVLP

- Number of coats: 2-3 (minimum); It's important to ensure 8-12 mils of dry film thickness for a proper barrier coat.

- Thinner: TotalBoat Epoxy Primer Thinner 200

- Cleanup: TotalBoat Epoxy Primer Thinner 200 or TotalBoat Dewaxer & Surface Prep

- Coverage: 225 sq ft/gal (at 7 mils wet, not accounting for waste)

- Application temperature/RH: 50-90ºF; 0-85% RH

- Units of measure: Quart Kit and Gallon Kit in Gray

-

TotalProtect Epoxy Barrier Coat Primer

- High-build epoxy primer for corrosion protection or osmotic blister prevention

- Barrier coat

- Wood, fiberglass, metals, and previously painted surfaces in good condition (except for 1-part paints)

- Above or below

- Antifouling paints, topside paints, urethanes

- Brush: (natural bristle, solvent safe); Roll: (3/16" - 3/8" nap or foam solvent-safe roller cover), or Spray: Conventional, airless, HVLP

- 2-3 coats (minimum), when using a 3/8" roller cover; 3-4 coats, when using a 1/4" roller cover; 4-5 coats, when using a 3/16" roller cover

- TotalBoat Epoxy Primer Thinner 200

- TotalBoat Epoxy Primer Thinner 200 or TotalBoat Dewaxer & Surface Prep

- 225 sq ft/gal (at 7 mils wet, not accounting for waste)

- 50-90ºF; 0-85% RH

- Quart Kit or Gallon Kit in Gray or White

-

Premium Marine Topside Primer

- Fast-drying one-part primer for one-part and two-part topside finishes

- Tie coat primer

- Fiberglass, wood, previously painted surfaces, epoxy

- Above

- Polyurethane and enamel topside paints

- Brush, Roll, or Spray

- 1-2

- TotalBoat Special Brushing Thinner 100, for brushing and rolling applications; TotalBoat Spray Thinner 101, for spraying and cool weather brushing/rolling applications

- TotalBoat Dewaxer & Surface Prep or TotalBoat Special Brushing Thinner 100 or TotalBoat Spray Thinner 101

- 350-400 sq ft/gal

- 50-90ºF; 0-90% RH

- Gallons and Quarts (White and Gray)

YOU MAY ALSO LIKE

FREQUENTLY ASKED QUESTIONS

-

What applications are Aluminum Boat Barrier Coat Epoxy Paint Primer most appropriate for?

This 2-part, high-build epoxy primer features anti-corrosive properties ideal for protecting underwater metals like lead, bronze, cast iron, stainless, and aluminum. Apply to the bottoms of leaky aluminum boats to seal leaking rivets. Although it can fill tiny scratches and minor pits in aluminum, it is not meant to be used as a filler. For scratches, deformations, dents, and dings 1⁄16” deep or greater, use TotalFair epoxy fairing putty first, then sand smooth and overcoat. -

Can Aluminum Boat Barrier Coat be applied over existing paint?

The only paints this product may reliably be applied over are 2-part finishes in good condition, and fully cured. Do not apply Barrier Coat over any 1-part finish. Wipe paint down with Dewaxer, sand with 80 grit, remove all sanding residue, and wipe again with Dewaxer. When in doubt, remove the finish and sand or sandblast to clean, bright metal. -

Is this a self-etching primer?

No. You will need to sand down and wipe clean. See technical data sheet for Barrier Coat primer application detailed instructions. -

What is the best way to apply Aluminum Boat Barrier Coat?

This primer can be applied by brush (natural bristle, solvent-safe), roller (3/16″ nap or foam solvent-safe roller cover), or spray (conventional, airless, or HVLP). Reducer: Aluminum Boat Barrier Coat can be thinned with TotalBoat Epoxy Primer Thinner 200, as needed (up to 10% maximum). -

What do I need to know before applying antifouling paint over Aluminum Boat Barrier Coat?

Barrier Coat must be fully cured and sanded before applying any water-based antifouling paint. For solvent-based antifouling paint, use the “thumbprint” method to determine if it is within the “overcoat window.” For Teflon or vinyl paints, Aluminum Boat Barrier Coat must be fully cured for 24 hours and sanded before applying antifouling paint. -

How many coats of this barrier coat do I need to apply?

We advise applying 2-3 coats at minimum. It’s more important to ensure 8-12 mils of dry film thickness (DFT), and more than 3 coats may be required to achieve 8-12 mils DFT. Failure to apply proper mil thickness may result in coating failure or potential water permeation. -

Do I need to apply a finish coat or can I use the primer as a finish?

Aluminum Boat Barrier Coat Epoxy Primer is not a finish. For applications below the waterline, we recommend a compatible antifouling (bottom) paint, especially a copper-free one that won't put aluminum at risk for galvanic corrosion. For topside applications, we recommend a polyurethane finish like Wet Edge for high gloss and vivid colors. -

What is the typical coverage of this primer?

225 sq. ft. per gallon (at 7 mils wet, not accounting for any waste). -

How long does it take for this primer to dry?

Dry times depend on temperature. The dry time for additional coats of Aluminum Boat Barrier Coat is 2 hours to 60 days at 90ºF, or 3 hours to 60 days at 70ºF. The dry time to overcoat with antifouling paint is 3 to 6 hours at 90ºF, 5 to 8 hours at 70ºF, or 7 to 10 hours at 50ºF. The dry time to launch (at minimum) is 12 hours at 90ºF, 24 hours at 70ºF, or 5 days at 50ºF.