It’s been over three years since we’ve featured Nike from White Spot Pirates, so we were very excited when she reached out recently needing help tackling some updates! Nike's aluminum sailboat, Karl, was left in Marina Chapers to weather the hurricane season. After over three years since its last antifouling paint job, Karl's hull had gathered an impressive collection of marine growth. Though not the worst, the hull required serious attention before returning to the water.

The Haul-Out

Before hauling Karl out, Marina Chapers required a clean hull. With the help of Ronnie and Yoyo, Nike tackled Karl's marine growth, scraping off the barnacles and algae. Once the hull was clear, Karl was lifted out of the water. The plan was to keep Karl on the hard for roughly three months. The primary task was a fresh coat of bottom paint, but other items on the to-do list included removing the rub rail, repairing the swim ladder, and giving the anchor some TLC.

A Fresh Bottom Job

Grinding down Karl's hull was quite the effort. With thousands of barnacle feet stuck to the paint, Nike had to grind down to get a smooth surface for the new paint. Even with Andy's help for a few hours, it took three days to grind the entire hull. Surprisingly, Nike found the job to be grinding between the keels to be the most comfortable part.

Here is Nike's usual process for preparing the bottom job on the aluminum hull:

- Grinding Down the Hull: Nike starts by grinding down the hull to remove all marine growth and old paint.

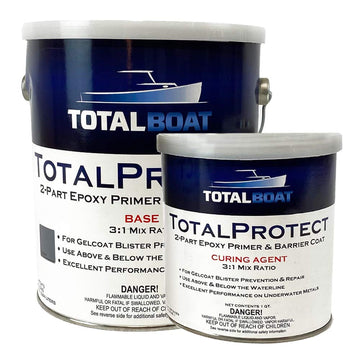

- Tackling Bare Aluminum Spots: Any bare aluminum spots where the paint has peeled away get four to five layers of TotalProtect Epoxy Primer & Barrier Coat.

- Cleaning and Degreasing: The entire hull is cleaned and degreased to prepare for the primer.

- Applying Primer: A full layer of two-component epoxy primer is applied to create a solid base for the antifouling paint.

- Applying Antifouling Paint: Once the primer is tacky, the first layer of TotalBoat Krypton Copper-Free Antifouling Bottom Paint which is ablative, is applied. Then a second layer and a third layer along the waterline for extra protection against friction are added.

In preparing the bare aluminum spots, Nike used TotalBoat Aluminum Boat Etch Wash Cleaner and Conditioner. This wash removes the oxidation layer on aluminum, allowing the primer to adhere properly. Timing was crucial—the wash needed to stay on the aluminum for five minutes without drying out, which was tricky in the warm conditions. Then, within an hour, the epoxy primer had to be applied to ensure proper adhesion.

Despite the challenges, Nike managed to apply the primer and prepare Karl's hull for the new antifouling paint. Seeing Karl's fresh, smooth hull ready for the water again was incredibly satisfying!

Make sure to subscribe to WhiteSpotPirates for more updates on Karl's transformation and the various projects tackled during Nike’s time on the hard!