Meet Lukas Hart: varsity athlete, marching band captain, student government leader—and boat builder. A driven high school student with a love for hands-on learning and creative problem solving, Lukas took on a challenge that most adults wouldn’t dare to tackle. Inspired by childhood memories of creek-side adventures and fueled by a passion for woodworking, Lukas set out to build a boat in his school’s woodshop class—becoming the first student at Mahwah High School to do so.

What started as sketches in a notebook quickly turned into a multi-year endeavor requiring steam-bending wood, salvaging mahogany, and mastering fiberglassing techniques. With guidance from his woodshop teachers, support from family, and encouragement from the TotalBoat team, Lukas brought his vision to life one painstaking step at a time. Along the way, he documented the build on Instagram, inspiring fellow students and boat lovers alike, while gaining experience that’s already shaping his future.

From test floats in the family pool to a fully detailed interior inspired by Italian Riva yachts, Lukas’s boat reflects his perseverance, craftsmanship, and youthful determination. In this spotlight, we dive into his journey—from humble beginnings and early setbacks to major milestones and future aspirations in naval architecture.

Can you tell us a little about yourself and how you first got interested in woodworking and boat building?

I am a student who loves school. I engage myself in challenging classes and leadership positions such as student government and multiple STEAM-focused clubs. In the fall I was captain of the varsity soccer team while also being a captain in the Marching band where both groups competed and won games/events in the state tournaments (did not win the whole tournament).

When I was about 8 years old I would explore the creek behind my grandparent's house in Pennsylvania. One day I told my grandpa I wanted a boat. So, he helped me go to the garage, cut a board with a triangulated tip, paint it, and attach a string to it. That was my first boat.

Above: Splashing his first boat.

From there my love for woodworking grew significantly in 7th grade when I set out in my basement with a couple of hand tools and a jigsaw to make gifts for my family and close friends for Christmas. From there I was hooked on making things for people for holidays and their birthdays. This passion continued to grow and the projects became more complex, more time-consuming, and more meaningful. (Some examples on my Instagram page of this are: Cooking spoons, purses, deer-antler knives, etc.)

Moving into high school my first woodshop class was Introduction to Wood and Furniture with Mr. Coe. Mr. Coe taught me methods and how to use more advanced woodworking tools than the small tools in my basement. I took woodshop as an opportunity to escape my other normal classes. I focused on every detail and every corner of every project becoming familiar with the personalized care and passion that goes into woodworking.

The next year I had Mr. Catizone as a woodshop teacher and from there, his inspiration and ability to work through challenging problems with me fueled my creative fire and I have yet to make a piece of “normal” furniture.

What inspired you to take on the challenge of building a boat in your high school woodshop class?

My inspiration for building the boat stems from my love for boating and my desire to push myself. My boat will be the first boat ever made at Mahwah High School and most likely one of the only high school built boats made by one person. I value the fact that I am pushing through new territory and opening up a field of opportunity for many more enthusiastic builders to come. Not everyone is going to build a boat I hope my journey fuels their ability to push close to whatever their goals may be.

Did you have any prior experience with boats, or was this a completely new venture for you?

Throughout my life, my family has always made an effort to travel and visit family. All my relatives in different parts of the country live near water and have a boat so boating was always an event multiple times a year. These experiences did not involve building or working on boats but they helped reinforce the idea that building a boat would all be worth it.

Walk us through your boat-building process. How did you go from concept to completion?

In late August of 2023 I began drawing the plans for my boat. I knew I wanted a boat big enough for at the least my dog Izzi and I and I took lots of inspiration from Riva boats based in Italy, following a similar interior layout as the Riva Aquarama. While at the time I understood my project would not be perfect, the design quality of boats like the Riva Aquarama is the standard I would hold myself to for the entirety of the project.

Going into my junior year and advanced woodshop class I already knew that the advanced students had the opportunity to take a whole year to make whatever they wanted. Finishing the drawings by September and the start of school, I brought them into Mr. Catizone and told him I wanted to build a boat, handing him my sketchbook. I remember him smiling at the drawings and immediately taking my sketchbook to show it to Mr. Coe in the office. I’m sure there were many things for Mr. Catizone to consider before approving my project but I was very excited when he told me I could do it. He made sure I knew that this project would likely take two years and that there would be many challenges along the way. In my head, the boat was already built and there was nothing that could stop me from making that vision come to reality.

From there I reached out to Totalboat over email with nothing to show but my drawings and enthusiasm. At first, like I had expected, Totalboat was a bit unsure in their first response. But then they emailed back soon after and a Totalboat epoxy kit with mixing buckets, squeegees, a hat and stickers was quickly on its way to Mahwah High School. This initial support was huge for me because it helped legitimize my project. This time was also the start of my instagram page.

From that point it was onto figuring out how to steam bend the structural ribs. Mr. Catizone was very enthusiastic about steam bending bringing in his own steam chamber, propane burner and knowledge. After I had made the molds to bend the wood around, I used ash that had not been kiln dried (still green) to bend. It didn’t work. The pieces kept splitting, some didn’t take the shape of the mold well and the metal band used to brace the wood as it was bent snapped and stuff went flying everywhere. But then I adjusted the thickness of the wood I was bending (going from close to 2” down to ~3/4-1”). And it worked. After about 5 unsuccessful attempts I was able to steam bend the first piece with the help of Mr. Catizone, Mr. Coe, and Ms. Loesche and myself all pushing on the metal band to make the wood take to the curve. From there momentum kept building and I had the all wooden frame assembled by the start of February. From there I traveled to Connecticut with my stepdad to get specific 1/4” marine grade plywood that apparently isn’t very common. This became the siding of the boat. About a month later, I was interviewed by the local newspaper and momentum kept building. Mr. Catizone when he is not teaching woodworking, runs a business of his own. On one of his jobs a customer wanted their full mahogany deck replaced. Conveniently, this 1” thick mahogany started showing up in the shop and I knew I had to use it. The boards started as painted tongue and groove flooring boards that I had to go over multiple times with a metal detector to remove rusty nails. After running these boards through all the necessary machines I glued the pieces into a rough shape of what I would need for my transom. From there I cut it, test fitted, cut it, test fitted, cut it, test fitted and cut it again until it fill well within the rear steam-bent frame piece. And then unfortunately the school year was up. Over the summer I took the boat home to a tent workshop my parents got for me in the backyard.

Over the summer after my job as a camp counselor, I would stay up until 11:30 most nights working on the boat. I poured expanding foam around the keel to get the shape I wanted. I filled the gaps between the strips of marine ply with bondo (very smelly process, full ventilation is definitely required-I learned the hard way on that one). Before I knew it August rolled around and my family was in town. My Uncle brought up a good point to me. “Why should you go forward and start making permanent final details if you don’t know if it floats yet?” My Stepdad agreed and being that they are both engineers I agreed with them too. We carried my boat from the tent to my pool where we gently set it down in the water. And it floated! We all got inside of it, my dog Izzi jumped in and then they got out and my cousins jumped in with Izzi. There was zero waterproofing at this point other than the small amounts of bondo between the pieces of plywood so naturally there was water actively flowing in but that didn’t matter.

Soon after it was time to take it back to school. I configured my schedule to maximize my time in the shop. On a great day I would have about 4 hours in the shop with a good day having somewhere around 2-3 hours. I went in after school almost every day, worked during my off-campus study halls, and poured every extra minute I had into working. I steam bent oak railings to the side and added a mahogany inlay on the inside to blend nicely with the interior. From there I cut, constructed and installed the mahogany strips to the boat staying to the standard of Riva Boats. After that I planned out the bench configuration, modifying my original design. I then installed structural rails for the flooring boards and benches followed by the construction of the benches and flooring boards. The pace of my work picked up and I was able to get much more done with extra time.

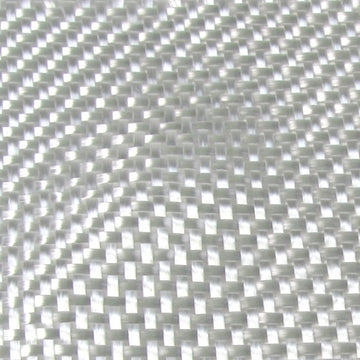

Following this I built the sliding door for the storage unit out of a piece of jatoba, a tropical cherry wood that was repurposed from a table top. And then it was flip time. After flipping the boat with the help of the school maintenance guy and his forklift I started sanding the hull, fiberglassing, priming, and painting. Totalboat during this process was very supportive and supplied me with most of the materials. After letting the paint set we flipped the boat again. Now I have started on interior finish work as I wrap up the project!

What were some of the biggest challenges you faced during the project, and how did you overcome them? Were there any moments during the build where you felt stuck or unsure, and how did you push through?

The biggest challenge and moment I felt most stuck during this project was steam bending the frame at the beginning of the project. This process involved seemingly endless failure and it was hard to keep pushing because there was nothing to show yet. However, after pushing through and adjusting I learned the process of trial, reassess, and retry. I knew in my head what I was working towards and it was all about making that vision real. I used that mentality with the continued support from my teachers to push forward. Even though this process was the hardest, the rest of the project would’ve never existed without this learning curve. The process of trial, reassess, and retry never went away but since I was conditioned to the feeling of it and had the adjusted mindset all the challenges after that did not stand a chance of stopping progress.

How did you decide what materials to use, and what role did TotalBoat products play in your build?

For choosing materials for this process I did extensive research on wooden boating forums, boat building school web pages, YouTube, and consulted my teachers, Totalboat, and family members of engineers and architects at each step of the way. There were always multiple options when choosing materials but Totalboat stood out to me because of their customer service and quality of product. Countless times I emailed or DM’d Totalboat on Instagram and they reached back out usually within the hour with helpful advice and they were able to provide me with what I needed most of the time. For the wood, water resistance was a key factor to look at when deciding what species to use. Mahogany is a great option so I made sure to use a lot of that as well as the marine grade plywood which is made with waterproof glue so it does not separate in water. For screws and other metal parts, everything for me has to be galvanized and coated over in epoxy or be stainless. I want to ensure the longevity of my boat in every way I can.

You’ve been great about sharing your progress with us. Why is it important for you to document and share your work?

Documenting my journey has been a necessary component of this project for a few reasons. One being that I have a place to show myself using Totalboat products and promoting their products. This process is important to me because it reinforces my collaboration with Totalboat and shows where their materials are going to. A second reason is the support I gain from this process. The amount of likes and views is not what I care about. Instead, it’s the people who have commented and DM’d me personally with advice, support and criticism. My project is far from perfect and I am aware of that. Interacting with people on social media has opened my perspective on my work to consider things I would not have otherwise thought of. The last reason for me is to have documentation of where it all started and what I overcame. My grandparents and parents regret not taking enough pictures or videos from their past experiences. With this form of documentation, I can spread my journey with anyone interested and hopefully they can realize big things are possible from smaller beginnings.

You were recently featured in a local article about your boat—how did that experience feel?

To be featured in a local article about my boat was awesome. It was one of the first times I had a chance to sit down and reflect on my progress to that point and helped me further refocus my goals for the future. This of course also added to my momentum and helped further legitimize my project.

Bergen County Teen Finally Tests Boat He Built In Wood Shop. Here's What Happened.

What kind of feedback have you received from friends, family, and the community about your project?

The feedback I have received has always been positive usually in the form of constructive criticism. I learn best from constructive criticism. This pattern of learning I believe closely resembles how I am taught during band rehearsals and it is very effective. Overall though, the community loves my boat and it gets shown off at board meetings, and people always, without fail, ask me about the progress when I meet with them.

Now that you've successfully built a boat, what’s next for you? Any future projects on the horizon?

At this point it is all about finishing my boat. There is still a lot to be done to the interior, motor, trailer, registration, etc. to get it on the water. For right now until about May when I estimate its completion, that is my main focus. Looking to the future, this is only the first boat. There is so much I have learned and so many things I can continue to develop that it would be a waste not to continue with boats. In addition to this, for me it is time to start designing my dream home. I anticipate to be designing it from now, all throughout college, and finally starting construction a few years after college. On the near horizon, I have many requests from teachers and students to help make things for their school clubs and things of the like. And on top of that, I am building furniture for American Reclaimed (a local reclaimed wood furniture store) and I have produced and will continue to produce unique products for them.

Has this experience influenced your future career plans? Do you see yourself continuing in the marine or woodworking industries?

Since I was a kid building legos without instruction packets, I knew I wanted to build bigger things when I got older. This experience of building my boat has reinforced this desire but it has also helped me key-in on what fields I am most interested in. No matter what I do or where I go I plan on finding a shop or building my own to continue my passion for woodworking. As of right now I have applied to a bunch of colleges and within these next few weeks I will have to make my decision. My top choice has a naval architecture and marine and engineering program and I am very interested in and the other schools I applied to majors focused in either engineering or architecture.

What advice would you give to other young builders who want to take on ambitious projects like yours?

The advice I would give to younger builders is to start small, be comfortable with every machine, and talk. Talk to your teachers, people who have done a similar project and people who are experts in the field. The connections you can make are vital to being able to grow. And one last thing is to be open to criticism and to know that if you get something right the first time, you might want to double check. Failure is inevitable and is usually to scale with the size and complexity of project. Never give in to failure and instead take a step back and find another way through it.

If you could build any type of boat in the future, what would it be and why?

If I could build any boat in the future I would build a nuclear powered private yacht. Right now nuclear powered motors are used in navy aircraft carries so I think scaling this down and putting it in a completely custom private yacht would not only be more efficient but it would not have a carbon footprint anywhere near a diesel powered. And of course I want to go to Riva Yachts and be involved with building boats there.

Lastly, what’s been the most rewarding part of this journey for you?

Currently I am looking forward to the most rewarding part of this project. Countless people have helped me by giving advice, donating, and supporting and in an effort to give back I plan on hosting an event where everyone is invited for a ride on the boat with the encouraged option of paying for a ticket to ride where 100% of the funds go towards a charity. This moment will be most rewarding for me.