PART OF THE TOTALBOAT TRADITIONAL EPOXY SYSTEM

Use with TotalBoat Traditional 5:1 Epoxy Resin.BEST FOR WORKING IN WARMER CONDITIONS

Extends working time and slows the cure time.EASY TO USE

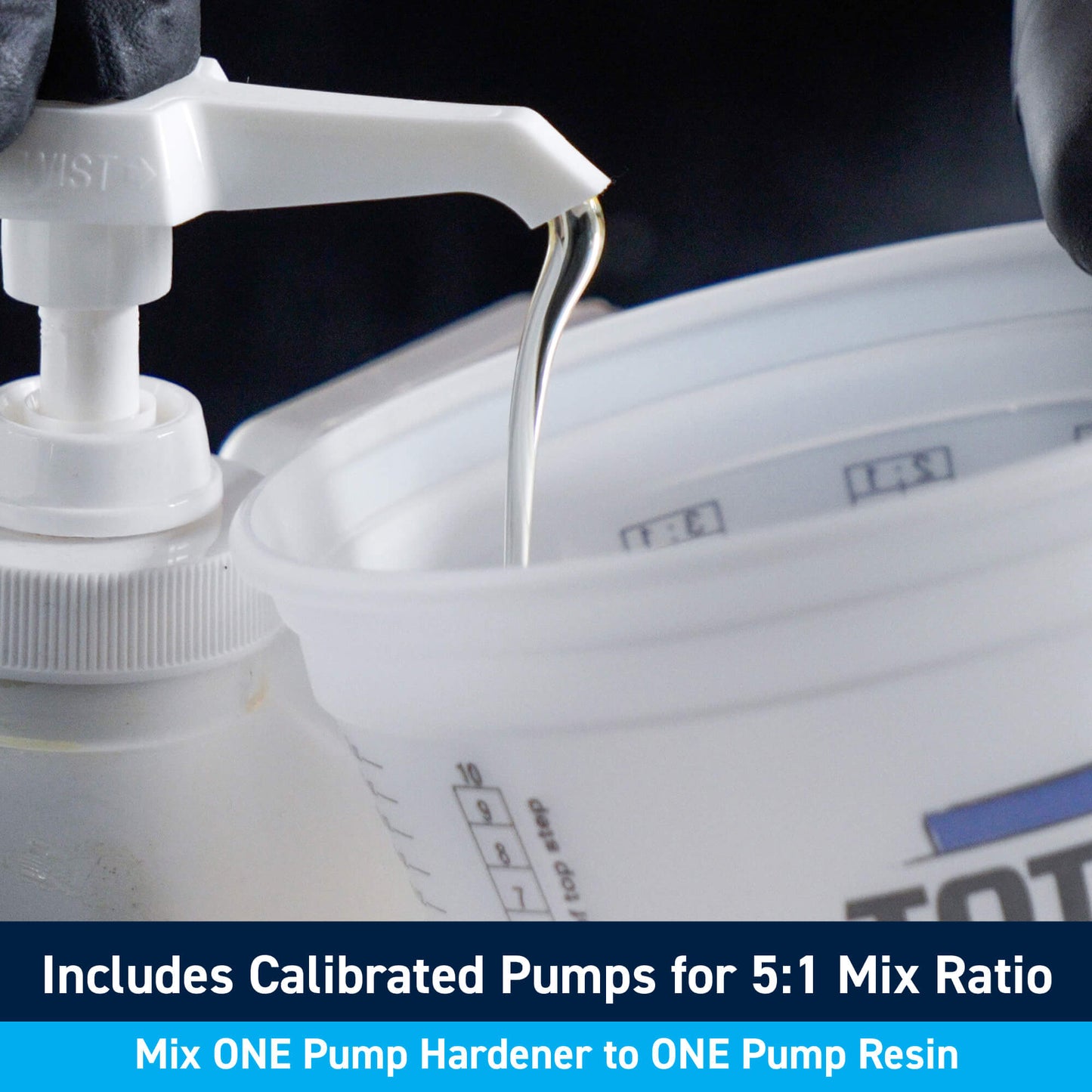

Simple 5A:1B mix ratio by volume. Easy to dispense with 5:1 pumps.ADJUSTABLE CURE TIME

Mix TotalBoat 5:1 Fast Hardener with 5:1 Slow Hardener to adjust the cure time.5:1 Slow Hardener

5:1 Slow Hardener

PART OF THE TOTALBOAT TRADITIONAL EPOXY SYSTEM

Use with TotalBoat Traditional 5:1 Epoxy Resin.BEST FOR WORKING IN WARMER CONDITIONS

Extends working time and slows the cure time.EASY TO USE

Simple 5A:1B mix ratio by volume. Easy to dispense with 5:1 pumps.ADJUSTABLE CURE TIME

Mix TotalBoat 5:1 Fast Hardener with 5:1 Slow Hardener to adjust the cure time.Couldn't load pickup availability

Stays workable longer so you have more time to get the job done

TotalBoat 5:1 Slow Hardener buys you a little more working time in warmer temperatures that tend to reduce working time and speed cure time of epoxy resins. You get a little more time to apply it because it won’t kick as fast.

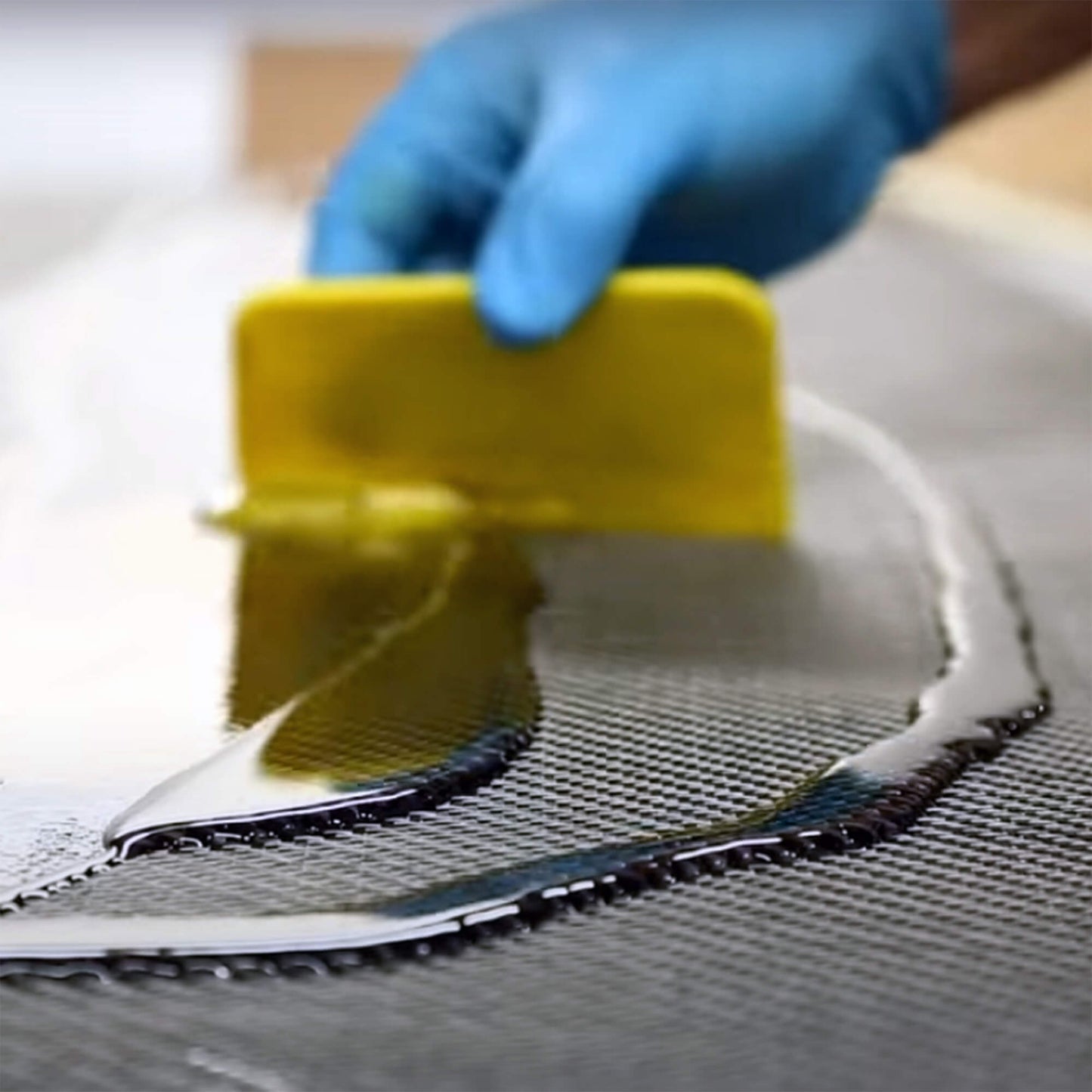

To get started, measure the mix of epoxy resin and hardener precisely, which is easy to do–especially with the pre-calibrated 5:1 Epoxy Pumps (sold separately). Combine 5:1 Slow Hardener with 5:1 Epoxy Resin in a five-part resin to one-part hardener ratio. Then spend about two minutes mixing thoroughly. The epoxy resin/hardener mixture can be used for wetting out fiberglass and other fabrics, coating, and bonding. The cured result is exceptionally strong and very moisture resistant.

Note: Epoxy pumps may not be compatible between brands. If using TotalBoat 5:1 Fast Hardener with a different brand of traditional 5:1 marine epoxy resin, be sure to confirm accurate mixing ratios based on the exact quantity each pump will yield. For best results, use either the TotalBoat Epoxy Pumps in the resin and hardener or the other brand’s pumps.

More 5:1 Slow Hardener Details

- In warmer temperatures (maximum 95°F), the 5:1 Epoxy Resin/Slow Hardener mixture remains workable longer, extending application time

- Cures to a moisture-resistant, high-strength, light amber finish when mixed with TotalBoat 5:1 Epoxy Resin

- Viscosity is preferred for ease in wetting out fiberglass and other fabrics

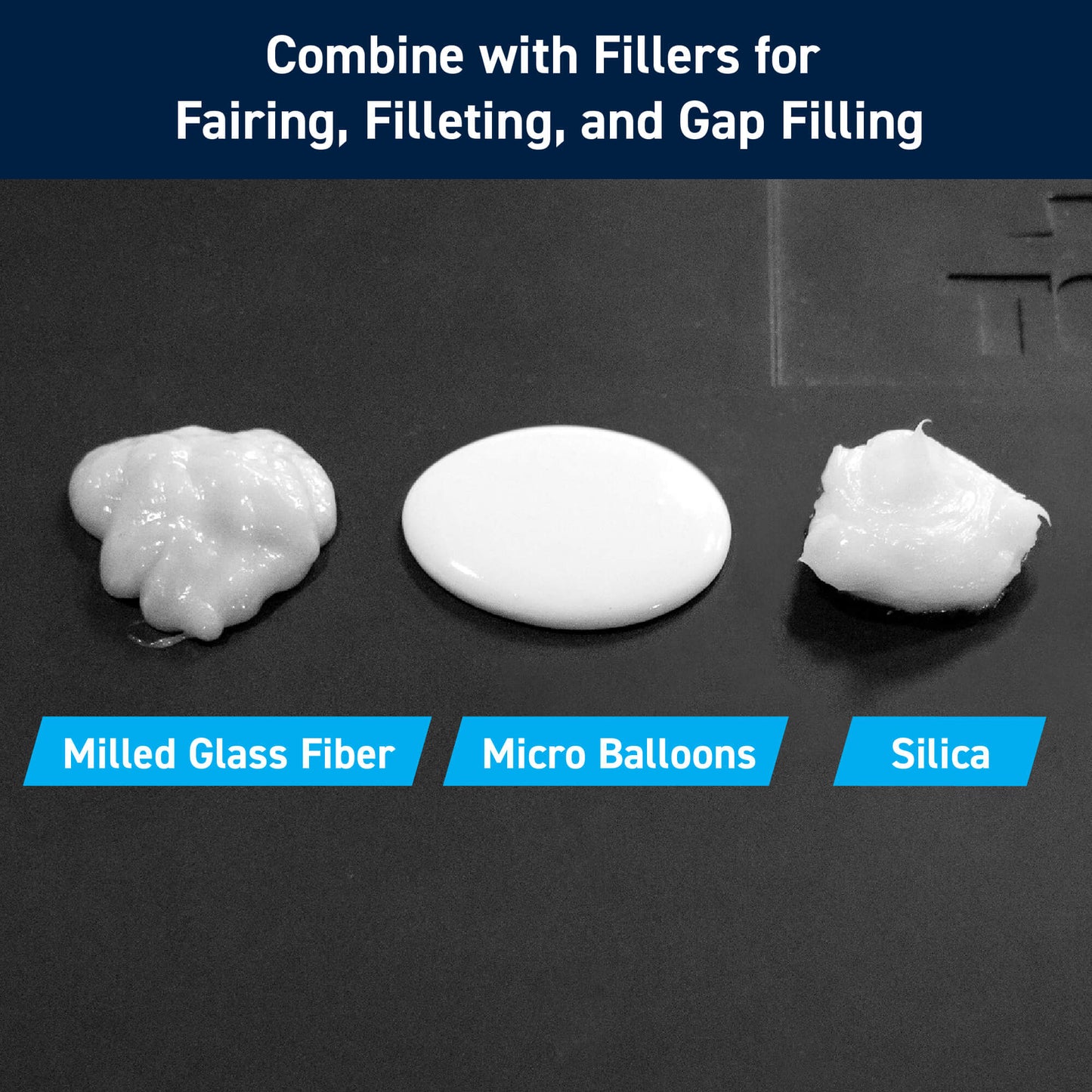

- Makes a strong filleting or fairing compound, or adhesive when combined with 5:1 Epoxy Resin and various thickening agents

- Excellent thin-film characteristics provide smooth flow-out and self-leveling ideal for coating and laminating

- Easy to measure and mix using pre-calibrated 5:1 Epoxy Pumps (sold separately), or, if preferred, by weight or volume

- Compatibility: TotalBoat 5:1 hardeners can be used interchangeably with other traditional 5:1 marine epoxy systems

- Sizes: Size A 6 fl. oz., Size B 25 fl. oz., and Size C 127 fl. oz. Note: Hardener sizes correspond to sizes of TotalBoat 5:1 Epoxy Resin

- 5:1 Slow Hardener is also available in a 10.4 gallon container, for use with drums of 5:1 resin. Please contact us for pricing

Important Safety Information

Always wear protective clothing and equipment to protect your eyes, skin, and lungs when working with TotalBoat Traditional Epoxy Resin and Hardeners. Personal protective clothing should include appropriate gloves, safety glasses or goggles, a proper respirator, and a proper apron or similar protective clothing.

SEE HOW EASY IT IS TO USE TOTALBOAT 5:1 TRADITIONAL EPOXY RESIN AND HARDENER

SEE HOW EASY IT IS TO USE TOTALBOAT 5:1 TRADITIONAL EPOXY RESIN AND HARDENER

TECHNICAL DATA

- Application Temperature (5:1 Epoxy Resin and 5:1 Slow Hardener): Approximately 70-95°F

- Minimum Recommended Temperature: 60°F

- Recommended Temperature for Dispensing by Pump: 60-70°F

- Pot Life @ 75°F: 20 minutes

- Set Time @ 75°F (Thin Film): 10 hours

- Cure Time @ 75°F (Thin Film): 1-4 days

- Note: Not intended for clear coating applications.

- Color: 5:1 Epoxy Resin (clear), Fast Hardener (amber); cures to a light amber color

- Mix Ratio by Volume: 5A:1B (5 parts epoxy resin to 1 part hardener)

YOU MAY ALSO LIKE