IDEAL FOR BOAT BUILDING

Perfect for epoxy repairs, fiberglass projects & marine composites.VERSATILE, MANY USES

Use for bonding, coating, laminating, fairing & filleting.TWO HARDENER SPEEDS

5:1 Fast and 5:1 Slow Hardeners for a range of applications.EPOXY SELECTION GUIDE

This chart will help you choose the right epoxy system5:1 Traditional Epoxy Resin Kits

5:1 Traditional Epoxy Resin Kits

IDEAL FOR BOAT BUILDING

Perfect for epoxy repairs, fiberglass projects & marine composites.VERSATILE, MANY USES

Use for bonding, coating, laminating, fairing & filleting.TWO HARDENER SPEEDS

5:1 Fast and 5:1 Slow Hardeners for a range of applications.EPOXY SELECTION GUIDE

This chart will help you choose the right epoxy systemCouldn't load pickup availability

The tough, water-resistant cure for whatever unfloats your boat

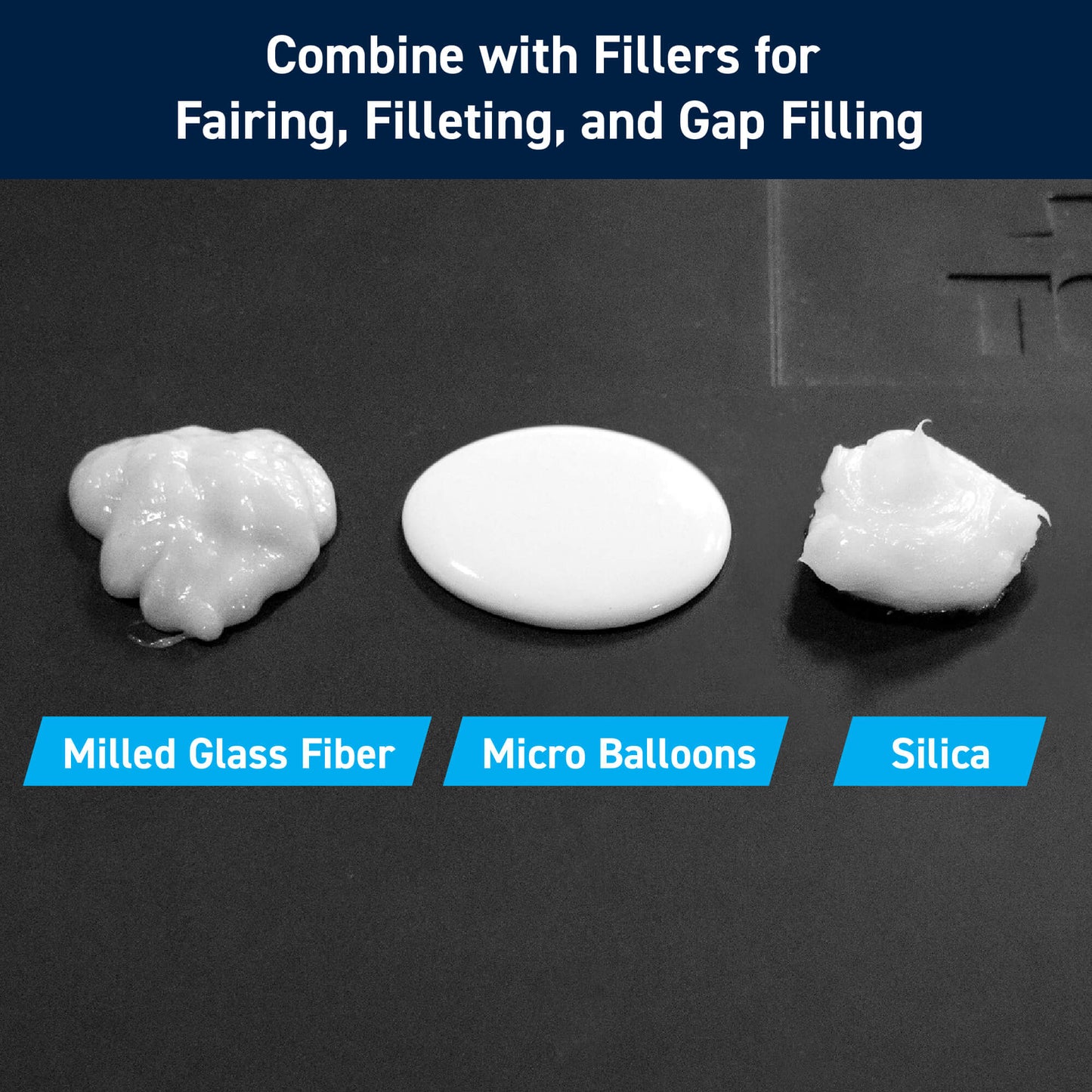

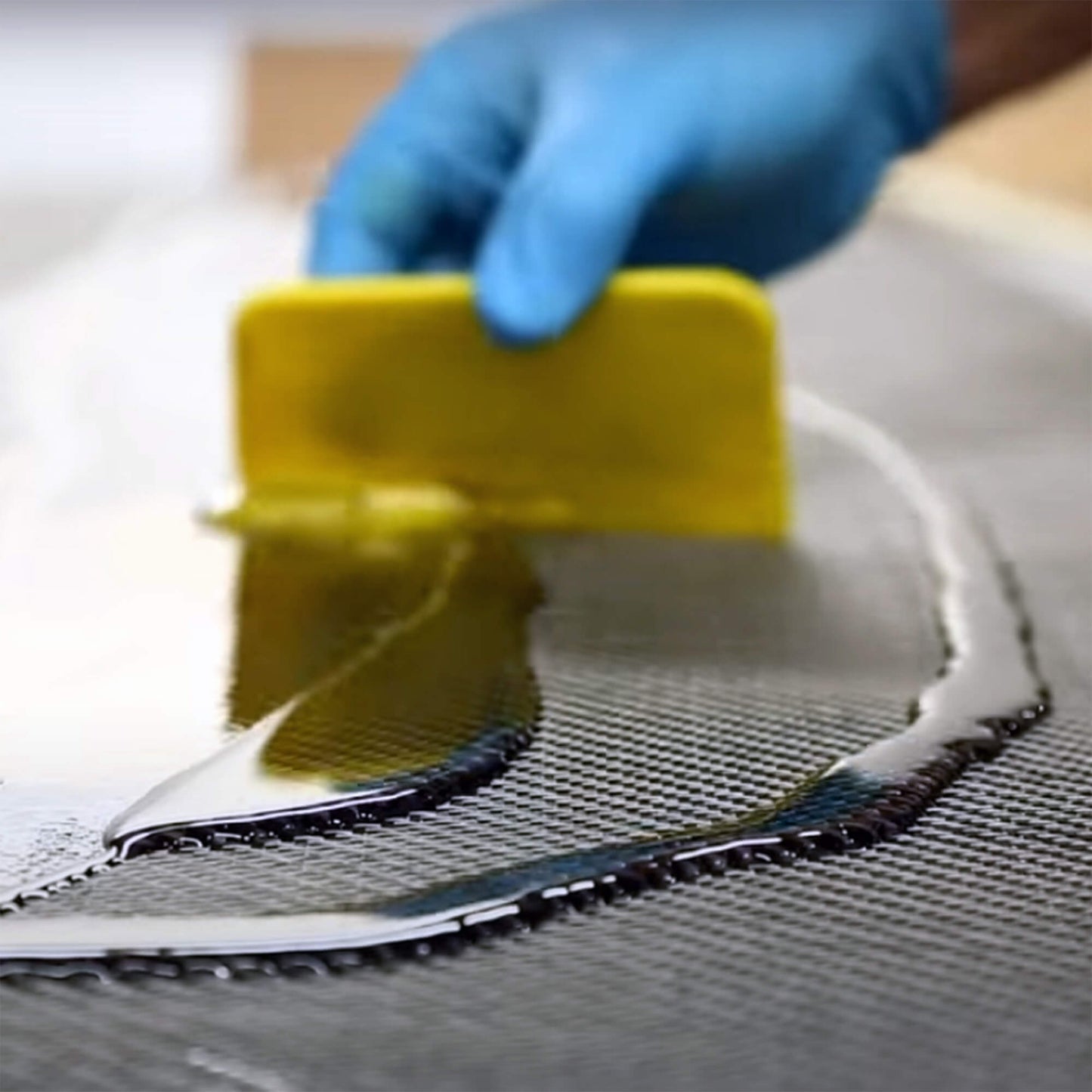

Have a chainplate that busted out of its bulkhead? A motor mount that came unmounted? Delaminated deck material? Cracks in your cuddy? No matter what shape your ship’s in, there are several projects epoxy can handle. It’s strong and won’t shrink in the face of daunting repairs. Literally. There’s nominal shrinkage, especially in larger repairs like replacing large sections of laminate. TotalBoat 5:1 Epoxy cures to a high-strength, water-resistant solid ideal for use in a variety of epoxy repair and fiberglass projects, including coating, bonding, and laminating. Add our fillers to the resin/hardener mix to get a strong adhesive, or a fairing and filleting compound that sands easily once cured.

Our epoxy resin kits make doing it yourself even easier

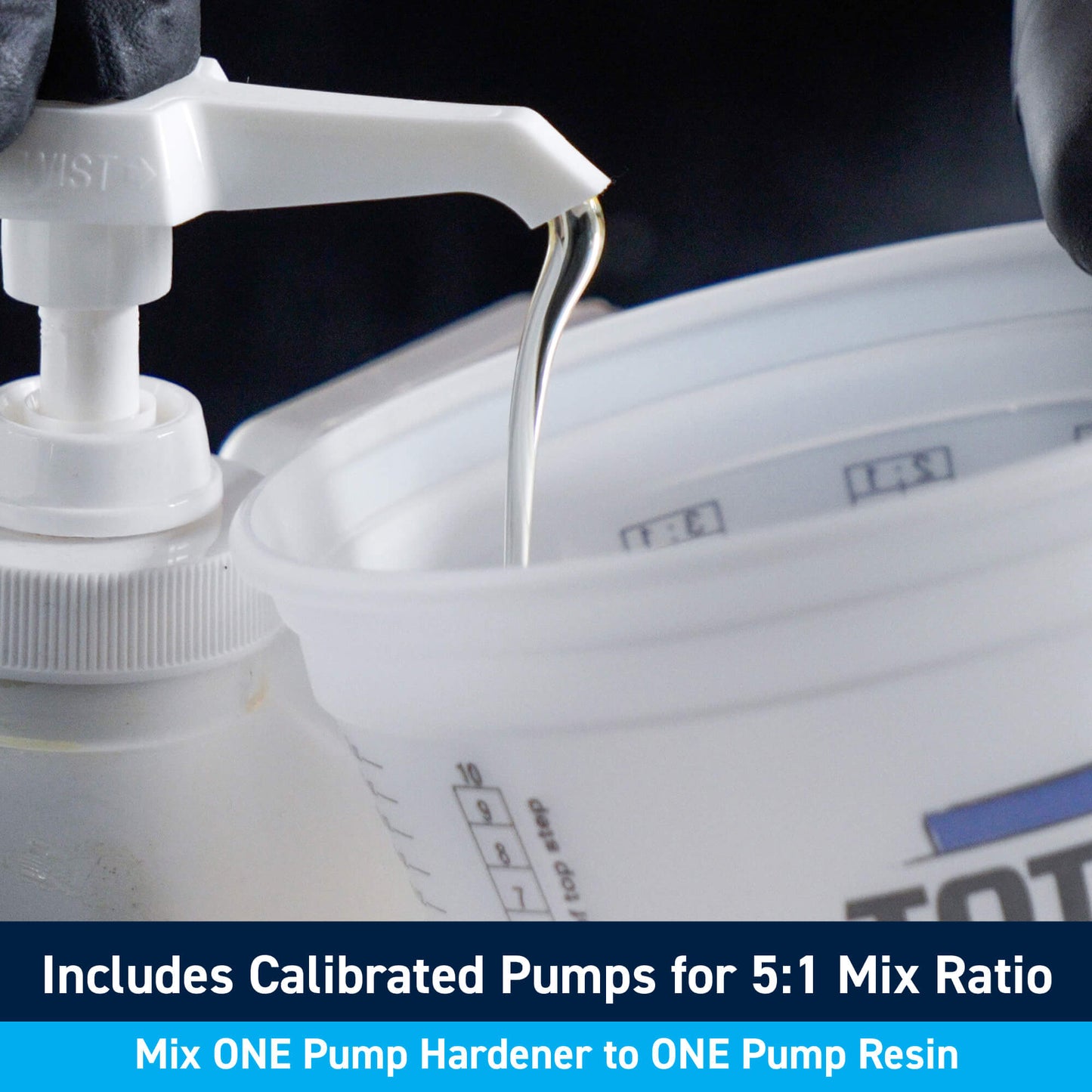

Whether you’re reinstalling berth frames and bulkheads, or you have an old wooden boat that needs some new skin, there’s enough stuff in our kits to make tough projects easier. You get the 5:1 Epoxy Resin and your choice of either Fast or Slow Hardener. Use the Fast Hardener in cooler temperature conditions to give you adequate working time and to speed up the curing time. The Slow Hardener extends the working and cure times in warmer temperatures. These complete, project-ready kits also have a set of calibrated pumps to dole out the resin and hardener in the precise mix of 5 parts resin to 1 part hardener. If you only need the 5:1 Epoxy Resin and Hardener, there’s a kit for that, too.

Our 5:1 epoxy resin kit system is compatible with traditional 5:1 marine epoxy systems

Still have another brand of resin or hardener left over from previous projects? You can use the TotalBoat 5:1 Epoxy system interchangeably with other traditional 5:1 marine epoxy systems, letting you can mix and match to use up those leftovers.

5:1 epoxy resin kits are interchangeable, but the pumps aren’t

Our epoxy resin and hardeners are packaged so there’s no wasted product. For example, the Size A 5:1 Epoxy Resin and the Size A Hardener are packaged so when they’re dispensed 5:1 — one push down on the white resin pump and one push down on the black hardener pump — the packages will eventually empty at the same time. When you buy new product, you can reuse your existing pumps, if you’ve kept them. The only thing that isn’t compatible are the pumps. If you’re using our 5:1 Epoxy Resin with another brand of hardener (or vice versa), you have three choices for measuring:

- Use TotalBoat containers and pumps: white for the resin and black for the hardener.

- Use the other brand’s containers and pumps for measuring resin and hardener at a 5:1 ratio.

- Measure the resin and hardener components by volume, not by pumps.

After measuring, just give the mix a good stir for about two minutes to combine thoroughly before applying. When all is said and done — and cured — you’ll get professional results without the professional’s bill.

Traditional Epoxy Resin Kit Details

- Epoxy resin kit options include quart or gallon sizes of 5:1 Epoxy Resin, with your choice of Fast or Slow hardeners, and with or without pumps, and cups.

- Viscosity is preferred for ease in wetting out fiberglass and other fabrics.

- Makes a strong filleting or fairing compound, or adhesive when combined with various thickening agents.

- Exceptional thin-film characteristics provide smooth flow-out and self-leveling ideal for coating and laminating.

- Easy to measure and mix using the precalibrated 5:1 Epoxy Pumps, which are color-coded to match the resin or hardener cap.

- Either of the 5:1 Fast and Slow Hardeners mixed with 5:1 Epoxy Resin cures to a slight amber color. Not intended for clear coat applications.

- Any amine blush upon cure is easily removed by scrubbing lightly.

- Compatibility: TotalBoat 5:1 Epoxy can be used interchangeably with other traditional 5:1 marine epoxy systems.

- Apply to fiberglass, reinforcing fabrics, wood, etched aluminum, and bare steel and lead.

- System Sizes: Group Size A – Quart Kit; Group Size B – Gallon Kit; Group Size C – 4.5 Gallon Kit

| Group Size | 5:1 Epoxy Resin Quantity | Fast or Slow Hardener Quantity | Mixed Quantity |

| A (Quart Kit) | 30 fl. oz. | 6 fl. oz | 36 fl. oz |

| B (Gallon Kit) | 127 fl. oz. | 25 fl. oz. | 152 fl. oz. |

| C (4.5 Gallon Kit) | 570.88 fl. oz. (4.46 gal.) | 127 fl. oz. | 697.88 fl. oz (5.45 gal.) |

Important Safety Information

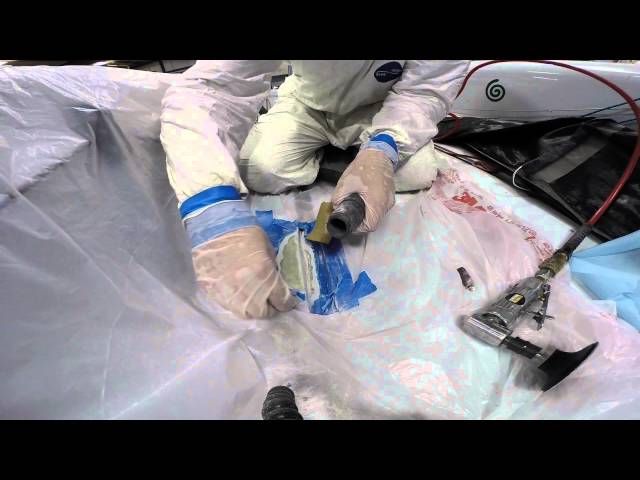

Always wear protective clothing and equipment to protect your eyes, skin, and lungs when working with TotalBoat Traditional Epoxy Resin and Hardeners. Personal protective clothing should include appropriate gloves, safety glasses or goggles, a proper respirator, and a proper apron or similar protective clothing.

FREQUENTLY BOUGHT TOGETHER

SEE HOW EASY IT IS TO USE 5:1 TRADITIONAL EPOXY RESIN

SEE HOW EASY IT IS TO USE 5:1 TRADITIONAL EPOXY RESIN

TECHNICAL DATA

- Application Method: Brush, Roller, or Syringe; can also be poured and spread with an epoxy spreader

- Minimum Recommended Temperature (Fast Hardener): 40°F

- Minimum Recommended Temperature (Slow Hardener): 60°F

- Recommended Temperature for Dispensing by Pumps: 60-70°F

- Pot Life @ 75°F: 12 minutes (Fast Hardener); 20 minutes (Slow Hardener)

- Substrates: Fiberglass, epoxy, wood, prepared metals, masonry, concrete, glass, stone & some plastics

- Color: 5:1 Epoxy Resin (clear), Fast and Slow Hardeners (amber)

- Mix Ratio by Volume: 5A:1B (5 parts resin to 1 part hardener)

- System Sizes: Group Size A – Quart Kit; Group Size B – Gallon Kit; Group Size C – 4.5 Gallon Kit

-

5:1 Traditional Epoxy Resin Kits

- Best for:

- Cured color:

- Mix ratio by volume:

- Mix ratio by weight:

- Maximum pour depth per layer:

- Application temperature/RH:

- Working time:

- Full cure time:

- BPA free?

- UV resistant?

- Units of measure:

- THIS ITEM

-

5:1 Traditional Epoxy Resin Kits

- Best for: Boat building and repairs, fiberglass projects & marine composites

- Cured color: Clear/amber

- Mix ratio by volume: 5A:1B

- Mix ratio by weight: 100A:18B

- Maximum pour depth per layer: Less than 1/8"

- Application temperature/RH: 5:1 Slow Hardener - minimum 60°F; 5:1 Fast Hardener - minimum 40°F; 0-90% RH

- Working time: 5:1 Slow Hardener - 20-45 minutes @ 75°F; 5:1 Fast Hardener - 10-25 minutes @ 75°F

- Full cure time: 3-5 days @ 75°F

-

BPA free?

• 5:1 Slow Hardener IS NOT BPA free

• 5:1 Fast Hardener is BPA free - UV resistant? No

- Units of measure: Quart Kit, Gallon Kit, 4.5 Gallon Kit

-

Clear High Performance Epoxy Kits

- Boat building and repairs, glassing projects & clear coating applications

- With 2:1 Slow Hardener - Clear; 2:1 Medium Hardener - Clear; 2:1 Fast Hardener - Clear/light amber

- 2A:1B

- With 2:1 Slow Hardener - 100A:45B; 2:1 Medium Hardener - 100A:45B; 2:1 Fast Hardener - 100A:46B

- • 2:1 Slow Hardener - 1/4", up to 75°F, for larger pours, slabs; 1/8", over 75°F, for larger pours, slabs; 3/8", up to 75°F, for smaller castings using up to 1 oz. of epoxy; 1/4", over 75°F, for smaller castings using less than 4 oz. of epoxy

• 2:1 Medium Hardener - 1/8"

• 2:1 Fast Hardener - Less than 1/8" - Minimum of 55°F, 0-90% RH

- With 2:1 Slow Hardener - 20-45 minutes @ 77°F; 2:1 Medium Hardener - 10-30 minutes @ 77°F; 2:1 Fast Hardener - 5-15 minutes @ 77°F

- With 2:1 Slow Hardener - 5-7 days @ 77°F; 2:1 Medium Hardener - 3-5 days @ 77°F; 2:1 Fast Hardener - 2-5 days @ 77°F

- Yes

- No

- Pint Kit (1.5 pints total), Quart Kit (1.5 quarts total), Gallon Kit (1.5 gallons total), 2 Gallon Kit (3 gallons total)

-

Penetrating Epoxy Sealer

- Sealing new wood or restoring rotten wood

- Clear

- 2A:1B

- 100A:44B

- Less than 1/16"

- Regular formula 65°F-90°F; Cold Weather formula - 40°F to 65°F

- regular formula - 20 minutes @ 80°F; Cold Weather formula - 40 minutes @ 40°F

- Regular formula - 2 days @ 80°F; Cold Weather formula - 4 days @ 40°F

- Yes

- No

- Pint Kit, Quart Kit, Half-Gallon Kit, Gallon Kit

-

Table Top Epoxy Resin Kits

- Coating table tops and bar tops with a high-gloss finish; Small castings with a pour depth up to 1"

- Clear

- 1A:1B

- 1.2A:1B

- 1/8" - 1/4"

- 70°F to 80°F, 0-85% RH

- 40 minutes @ 77°F

- 5-7 days

- Yes

- Yes - For superior UV protection, coat with UV-blocking varnish.

- 2 Quart Kit, Gallon Kit, 2 Gallon Kit, 4 Gallon Kit

Watch More Videos

-

How To Use Epoxy Pumps

-

BlackWatch Carbon Fiber HardTop - Part 1

-

Fiberglass & Gelcoat Repair - Using Gelcoat Over Epoxy

-

How to Safely Plug a Hole Below the Waterline | Boat Repair with Andy Miller of Boatworks Today

YOU MAY ALSO LIKE

FREQUENTLY ASKED QUESTIONS

-

What is the difference between Fast Hardener and Slow Hardener?

Use the Fast Hardener in cooler temperature conditions to speed up curing time while still providing adequate working time. The Slow Hardener extends the working and cure times in warmer temperatures. Slow Hardener is not recommended for use in cool temperatures. -

Is TotalBoat 5:1 Epoxy UV-protected?

All epoxies will discolor, turn brittle, and eventually disintegrate upon prolonged UV exposure unless topcoated with a UV-resistant varnish or polyurethane finish. Be sure to sand cured epoxy before topcoating. -

Should I sand epoxy between coats?

When applying additional coats of resin to dried epoxy, sanding improves the mechanical bond. Before sanding, be sure to remove any amine blush. Once cured, this epoxy can be sanded and shaped. -

Is Traditional 5:1 Epoxy Resin Kits a non-blushing system?

No, it will blush upon cure. Amine blush is a normal byproduct of curing and is easily removed. -

Can this epoxy resin be thinned?

Do not thin TotalBoat 5:1 Epoxy; we recommend Penetrating Epoxy if you need a thin or low-viscosity epoxy. -

How should I apply this resin?

You can apply epoxy resin with a brush, roller, or syringe. It can also be poured and spread with an epoxy spreader. -

Does TotalBoat Traditional Epoxy dry clear?

TotalBoat 5:1 epoxy cures to a slight amber color. It is not intended for clear coat applications. We recommend High Performance 2:1 Epoxy for applications where the clearest possible finish is important -

How many square feet will a one-gallon system cover?

Using typical 6 oz fiberglass cloth, a gallon of resin will cover about 10 sq yards or 90 sq ft of cloth. -

Is this resin compatible with fillers?

Yes. All common fillers like cabosil, wood flour, milled glass fibers, microballoons, and others may be added to 5:1 Epoxy to create compounds used for fillets, fairing, bonding, and gap filling. -

What is the minimum temperature suggested for working with this product?

The minimum recommended temperature for the Fast Hardener is 40°F. The minimum recommended temperature for the Slow Hardener is 60°F. -

Is TotalBoat Traditional 5:1 Epoxy compatible with other epoxy systems?

Yes, TotalBoat 5:1 Epoxy can be used interchangeably with other traditional 5:1 marine epoxy systems. Important: Do not use TotalBoat pumps with other brands. Be sure to mix by volume only. -

What is the working time?

Pot life ranges from 12 minutes at 75°F for Fast Hardener, to 20 minutes at 75°F for Slow Hardener. Set time ranges from 6 hours at 75°F for Fast Hardener, to 10 hours at 75°F for Slow Hardener. Cure time ranges from 1-4 days at 75°F for Fast Hardener and Slow Hardener. -

Will epoxy still cure if mixed at an incorrect ratio?

No, unlike polyester resin, epoxies require a very specific resin to hardener ratio in order to cure properly. You will need to remove the epoxy and start over. Solvents like acetone may be used to remove the uncured resin. -

How should I properly store TotalBoat epoxy?

Store at 60-90°F in a dry place. After use, tightly reseal all containers. Store products on a raised surface off the floor during cold weather and avoid storing near outside walls or doors. Properly stored, this epoxy has no specific shelf life.